what is cone clutch ?

A cone clutch is a type of mechanical clutch used in various machines and vehicles to transmit power between two rotating shafts. It belongs to the category of friction clutches, which work based on the principle of frictional force between two surfaces.

Must Read : Centrifugal Clutch

cone clutch parts

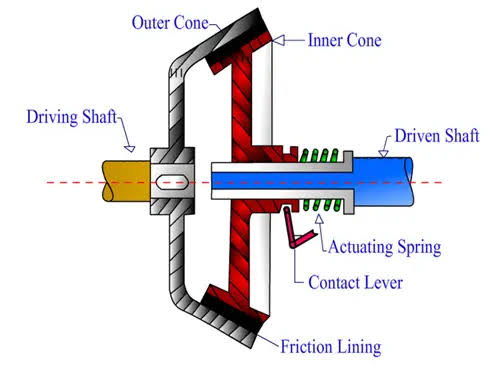

A cone clutch consists of several parts that work together to facilitate power transmission and engagement. The main parts of a cone clutch are as follows:

- Driving Member: The driving member is usually a shaft that is connected to the engine or motor and provides the power to the clutch.

- Driven Member: The driven member is also a shaft, which is connected to the load or the machine’s output. It receives the power from the driving member when the clutch is engaged.

- External Cone: The driving member has an external conical shape, also known as the male cone, which fits into the corresponding internal conical bore of the driven member.

- Internal Cone: The driven member has an internal conical bore, known as the female cone, that matches the shape of the external cone of the driving member.

- Clutch Pedal or Lever: In vehicles or machinery, the clutch pedal (in manual vehicles) or the clutch lever (in machinery) is used to actuate the clutch and engage or disengage the power transmission.

- Release Bearing: In some cone clutch systems, a release bearing is used to facilitate smooth engagement and disengagement of the clutch. The release bearing applies pressure to the clutch, allowing it to engage or disengage smoothly when the clutch pedal or lever is actuated.

- Clutch Housing: The clutch housing houses the clutch components and helps protect them from external elements. It also provides support and keeps the clutch components aligned.

- Friction Material: The conical surfaces of the driving and driven members are often lined with friction material. This friction material enhances the clutch’s grip and enables efficient power transmission through the frictional force generated between the conical surfaces.

- Springs or Actuators: Some cone clutch designs incorporate springs or other types of actuators to assist in disengaging the clutch when the clutch pedal or lever is released. These components aid in separating the driving and driven members, ensuring smooth disengagement.

These are the key parts of a cone clutch that work together to enable smooth engagement and disengagement of power transmission. The precise design and construction of the cone clutch may vary depending on the specific application and engineering requirements.

cone clutch working principle

The working principle of a cone clutch involves the transmission of power between two rotating shafts by using the frictional force generated between two conical surfaces. One conical surface is attached to the driving member (usually a shaft connected to the engine or motor), and the other conical surface is connected to the driven member (typically a shaft connected to the load or the machine’s output).

How does cone clutch works

A cone clutch works based on the principle of friction between two conical surfaces to transmit power between two rotating shafts. It operates as follows:

- Engaging the clutch: When the clutch pedal (in a vehicle) or the clutch lever (in machinery) is pressed or actuated, it initiates the engagement process. In vehicles, this is often referred to as “stepping on the clutch pedal.”

- Axial movement: The pressing of the clutch pedal or lever causes the driving member’s conical surface to move axially towards the driven member’s conical surface. This axial movement brings the two conical surfaces closer to each other.

- Friction generation: As the conical surfaces come into contact, friction is generated between them. The coefficient of friction between these surfaces ensures that a considerable amount of torque can be transmitted between the driving and driven members.

- Power transmission: The frictional force at the interface of the conical surfaces allows the driving member to transmit power to the driven member. The torque from the engine or motor is now transmitted to the load or the machine’s output, causing it to rotate.

- Disengaging the clutch: To disengage the clutch and stop the power transmission, the clutch pedal or lever is released. This action causes the driving member’s conical surface to move away from the driven member’s conical surface, breaking the contact between the two surfaces.

- Power cutoff: With the contact broken, the frictional force between the conical surfaces is eliminated, and power transmission ceases. The driving and driven members can now rotate independently.

The smooth engagement and disengagement of the cone clutch, as well as its ability to handle high torque loads, make it suitable for various applications, especially in manual transmissions of vehicles and certain industrial machinery. However, it’s important to ensure proper maintenance and periodic checks to keep the friction surfaces in good condition and maintain the clutch’s efficiency and longevity.

cone clutch Troubleshooting

Troubleshooting is the process of identifying and resolving issues or problems that occur in a system, machine, or device. It involves systematic investigation and analysis to determine the root cause of the problem and then implementing appropriate solutions to fix it. Troubleshooting is commonly used in various fields, including technology, engineering, electronics, automotive, and more.

Here are some general steps for effective troubleshooting:

- Identify the Problem: The first step is to identify and define the specific issue or problem. Gather as much information as possible about the symptoms, error messages, or unusual behavior of the system.

- Check for Obvious Causes: Look for any obvious and easily fixable causes of the problem, such as loose connections, disconnected cables, or depleted power sources.

- Review Manuals or Documentation: Consult the system’s manuals, guides, or technical documentation to understand how the system is supposed to function and to find troubleshooting tips specific to the system.

- Isolate the Cause: Try to isolate the root cause of the problem by narrowing down potential issues. This can be done by testing different components or subsystems separately.

- Use Diagnostic Tools: If available, use diagnostic tools or software that can help identify the problem and provide specific error codes or information.

- Check for Software Updates: In the case of software-related issues, make sure that the system’s software and drivers are up-to-date. Sometimes, updates can fix known bugs and issues.

- Test and Verify: Conduct tests and simulations to verify the identified problem and the effectiveness of any potential solutions.

- Implement Solutions: Based on the analysis and diagnosis, implement the necessary solutions or repairs to fix the problem. This may involve replacing faulty components, adjusting settings, or updating software.

- Test Again: After implementing the solutions, perform additional tests to ensure that the problem has been resolved and that the system is functioning correctly.

- Document the Solution: It’s essential to document the troubleshooting process and the actions taken, as this information can be valuable for future reference or for sharing with others who may encounter similar issues.

Remember that troubleshooting can sometimes be a complex and iterative process, especially for intricate systems or devices. If the problem persists or you’re unsure about how to proceed, it’s best to seek help from experienced technicians or professionals with expertise in the relevant field.

application of cone clutch

Cone clutches find application in various machines and equipment where smooth and reliable power transmission is required. Some common applications of cone clutches include:

- Manual transmissions in vehicles: Cone clutches are used in manual transmissions of cars, motorcycles, and other vehicles to engage and disengage the engine power to the gearbox. The smooth engagement and disengagement provided by cone clutches make them suitable for use in vehicles, where drivers need to shift gears frequently.

- Industrial machinery: Cone clutches are used in industrial machines such as lathes, milling machines, and drilling machines to transmit power from the motor to the rotating spindle or shaft. They are also used in certain power tools like grinders and sanders.

- Marine applications: In marine propulsion systems, cone clutches are used to engage and disengage the power transmission from the engine to the propeller shaft. This allows the vessel’s speed and direction to be controlled efficiently.

- Agricultural equipment: Cone clutches can be found in agricultural machinery, such as tractors and combine harvesters, where they are used to transfer power between different components of the equipment.

- Printing presses: Cone clutches are used in printing machines to control the rotation and movement of printing cylinders.

- Textile machinery: In textile mills, cone clutches are used in machinery like spinning machines to control the power transmission to different parts of the equipment.

- Conveyors and material handling systems: Cone clutches can be employed in conveyor systems and material handling equipment to control the movement and stoppage of loads.

In these applications, cone clutches are preferred due to their ability to provide gradual and smooth engagement, reducing wear and tear on the components, and offering reliable power transmission. However, it’s worth noting that in some modern applications, other types of clutches, such as multi-plate clutches or electromagnetic clutches, have been adopted for specific advantages they offer.

advantages of cone clutch

Cone clutches offer several advantages that make them well-suited for specific applications. Some of the main advantages of cone clutches include:

- Smooth engagement: Cone clutches provide gradual and smooth engagement, which reduces shock and wear on the drivetrain components. This feature is particularly beneficial in vehicles and machinery where precise control over power transmission is required, resulting in a comfortable and efficient operation.

- Reliable power transmission: Cone clutches offer a reliable and positive connection between the driving and driven shafts. Once engaged, they provide a solid link, ensuring efficient power transfer without slippage under normal operating conditions.

- High torque capacity: Cone clutches can handle high torque loads, making them suitable for various industrial applications, such as lathes, drilling machines, and other heavy machinery.

- Simple design and construction: Cone clutches have a relatively simple design with fewer components, making them easier to manufacture and maintain. Their simplicity contributes to cost-effectiveness and ease of installation.

- Compact size: Compared to some other types of clutches, cone clutches can be more compact, which is beneficial when space is limited, such as in automotive applications.

- Ability to tolerate misalignment: Cone clutches can tolerate a certain degree of misalignment between the driving and driven shafts. This flexibility can help compensate for minor alignment issues and reduce the risk of damage due to misalignment.

- Durability: When properly maintained, cone clutches can be highly durable and have a long service life, making them suitable for heavy-duty applications.

- Manual control: In vehicles with manual transmissions, cone clutches allow drivers to have direct control over gear changes, enabling a more engaging driving experience.

- Cost-effective: The simplicity of the cone clutch design and its ease of manufacturing contribute to cost-effectiveness, making it a practical choice for many applications.

- Compatibility with different materials: Cone clutches can work effectively with a variety of friction materials, such as organic materials or sintered materials, allowing manufacturers to choose the material that best suits the application requirements.

These advantages have led to the continued use of cone clutches in various applications, especially in situations where their specific benefits align with the needs of the system or equipment. However, as technology evolves, alternative clutch types are also utilized in situations where specific performance characteristics are required.

disadvantages of cone clutch

While cone clutches have several advantages, they also come with some disadvantages, which may affect their suitability in certain applications. Some of the main disadvantages of cone clutches include:

- Heat generation: Cone clutches can generate significant amounts of heat during engagement and disengagement due to the friction between the conical surfaces. This heat can cause wear and reduce the clutch’s overall lifespan. In high-speed or heavy-duty applications, heat dissipation can become a challenge.

- Limited torque capacity: Cone clutches may have lower torque capacity compared to some other types of clutches, such as multi-plate clutches. This limitation can make them unsuitable for high-torque applications, especially in heavy machinery or high-performance vehicles.

- Wear and maintenance: The frictional surfaces of cone clutches experience wear over time, leading to the need for periodic maintenance and replacement of worn-out components. This maintenance requirement can increase downtime and operating costs for equipment using cone clutches.

- Slippage and judder: In some cases, cone clutches can experience slippage during engagement, leading to inefficiencies and potential damage. Moreover, during partial engagement, they may exhibit juddering or jerking motions, causing discomfort and reduced performance.

- Sensitive to misalignment: Cone clutches require precise alignment of the conical surfaces for smooth and effective engagement. Any misalignment can result in uneven contact and increased wear, reducing the clutch’s efficiency and reliability.

- Size and weight: In certain applications where space and weight are critical factors, cone clutches may not be the most compact or lightweight option. Other types of clutches, like electromagnetic clutches, can offer better space and weight efficiency.

- Operating limitations: Cone clutches may not be suitable for continuous slipping or engaging at high speeds due to the potential for excessive wear and heat generation. In applications where frequent and rapid clutch engagements are required, other types of clutches may be more appropriate.

Despite these disadvantages, cone clutches are still widely used in various applications where their advantages, such as smooth engagement and reliability, outweigh the drawbacks. However, in some modern systems, alternative clutch types have been adopted to address specific performance requirements and limitations.

cone clutch vs centrifugal clutch

Certainly! Here’s a comparison of cone clutch and centrifugal clutch in a table form:

| Aspect | Cone Clutch | Centrifugal Clutch |

|---|---|---|

| Working Principle | Friction between conical surfaces | Centrifugal force |

| Applications | Manual transmissions, industrial machinery | Small engines (lawnmowers, go-karts, etc.) |

| Engagement Control | Requires manual control (pedal/lever) | Engages and disengages automatically based on engine speed |

| Smooth Engagement | Yes | No |

| Torque Capacity | High | Limited |

| Precision Control | Yes | Less precise |

| Heat Generation | Possible at high speeds | Minimal |

| Number of Components | Relatively more | Relatively fewer |

| Cost-effectiveness | Moderate | Cost-effective |

| Maintenance Complexity | May require periodic maintenance | Low maintenance |

Please note that the characteristics mentioned above are general comparisons and may vary depending on specific designs and implementations of cone clutches and centrifugal clutches. The choice between the two types of clutches depends on the requirements of the application and the intended functionality.

Reference : https://en.wikipedia.org/wiki/Cone_clutch