what is a venturi meter ?

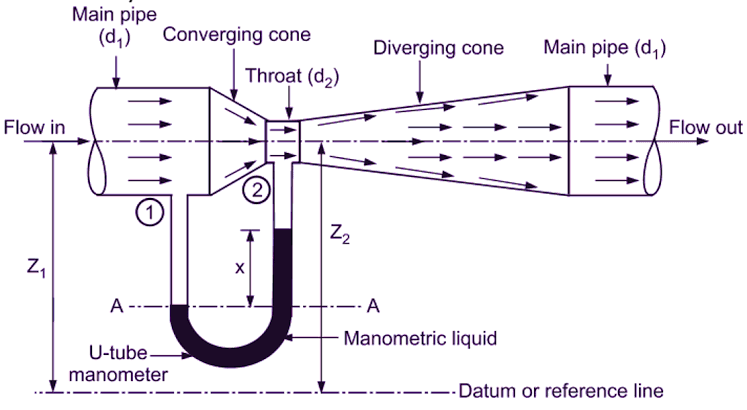

A venturi meter is a device used to measure the flow rate of a fluid in a pipe. It consists of a converging section, a throat, and a diverging section. The converging section gradually reduces the cross-sectional area of the pipe, causing the fluid to accelerate and its pressure to decrease. At the throat, the cross-sectional area is the smallest, creating the maximum fluid velocity and lowest pressure. Finally, in the diverging section, the cross-sectional area gradually increases, causing the fluid to decelerate and its pressure to rise again.

The pressure difference between the upstream and throat sections of the venturi meter is directly related to the flow rate of the fluid. By measuring this pressure difference, the flow rate can be determined using appropriate equations or calibration curves.

Venturi meters are commonly used in various industries, such as water supply, oil and gas, and chemical processing, to measure the flow rate of liquids and gases. They offer advantages such as low pressure drop, accuracy, and reliability. However, they require careful installation and calibration to ensure accurate measurements.

Must Read : Manometer

history

The history of the venturi meter dates back to the 18th century when Italian physicist Giovanni Battista Venturi made significant contributions to fluid dynamics and flow measurement. In the 1700s, Venturi conducted experiments and observations on fluid flow, particularly in relation to the principles of Bernoulli’s equation.

However, the modern venturi meter, as we know it today, was developed in the early 19th century. French engineer and physicist Henri Pitot, known for his work on fluid mechanics, made further advancements in flow measurement. He designed and introduced the Pitot tube, which utilizes the principle of pressure difference to measure fluid velocity.

Building upon Pitot’s work, French engineer Clemens Herschel further refined the concept and developed the Herschel venturi tube in the mid-19th century. Herschel’s venturi tube consisted of a tapered section that allowed for accurate flow measurement by utilizing the pressure difference between the converging and throat sections.

Over time, the venturi meter design continued to evolve, with improvements in accuracy, construction materials, and installation techniques. The venturi meter gained widespread recognition and acceptance in the field of flow measurement due to its reliability and accuracy compared to other types of flow meters.

Today, It is commonly used in various industries and applications, ranging from water supply systems, oil and gas pipelines, chemical processing plants, to HVAC systems. They have become an integral part of flow measurement technology, providing efficient and accurate measurement of fluid flow rates.

venturi meter diagram

venturi meter principle working

The venturi meter works based on the principles of fluid dynamics, specifically Bernoulli’s principle and the conservation of mass. Bernoulli’s principle states that as the speed of a fluid increases, its pressure decreases, and vice versa, when the fluid flows through a constriction.

In a venturi meter, the fluid flows through a converging section, a throat, and a diverging section. The converging section gradually narrows, causing the fluid to accelerate and its velocity to increase. According to Bernoulli’s principle, as the velocity increases, the pressure decreases. Thus, the pressure at the narrowest point, the throat, is lower than the pressure at the upstream section.

At the throat, where the cross-sectional area is the smallest, the fluid reaches its maximum velocity. This high velocity is associated with a further decrease in pressure. The pressure at the throat is the lowest point within the venturi meter.

As the fluid enters the diverging section, the cross-sectional area gradually expands, causing the fluid to decelerate. As a result, the pressure begins to rise again.

The pressure difference between the upstream section and the throat is measured using pressure taps located at these points. This pressure difference is directly related to the flow rate of the fluid passing through the meter.

By measuring the pressure difference, the flow rate through the venturi meter can be calculated using appropriate equations or calibration curves. These equations take into account the dimensions of the venturi meter, the fluid properties, and the pressure readings to determine the flow rate accurately.

Therefore, the venturi meter operates on the principle of utilising the pressure difference created by the change in cross-sectional area to measure the flow rate of a fluid.

venturi meter working step by step

The principle of operation of a venturi meter is based on the Bernoulli’s principle and the conservation of mass. It involves the measurement of the pressure difference created by the change in the cross-sectional area along the flow path. Here’s how a venturi meter works:

- Converging Section: The fluid enters the venturi meter through a gradually narrowing section called the converging section. As the cross-sectional area decreases, the fluid velocity increases according to Bernoulli’s principle. This increase in velocity is accompanied by a decrease in pressure, creating a pressure gradient along the converging section.

- Throat: The converging section leads to a narrowest point in the venturi meter called the throat. At the throat, the cross-sectional area is smallest, resulting in the maximum fluid velocity. This high velocity causes a further decrease in pressure, reaching the lowest point within the venturi meter.

- Diverging Section: After passing through the throat, the fluid enters the diverging section, which gradually expands the cross-sectional area. As the fluid moves into the diverging section, it begins to decelerate, and the pressure starts to rise again.

- Pressure Difference Measurement: The pressure difference between the upstream section and the throat of the venturi meter is measured using pressure taps located at these points. This pressure difference is directly related to the flow rate of the fluid passing through the meter.

- Flow Rate Calculation: By measuring the pressure difference, the flow rate through the venturi meter can be calculated using calibrated equations or flow rate conversion tables specific to the venturi meter design. These equations or tables take into account the dimensions of the venturi meter, the fluid properties, and the pressure readings to determine the flow rate accurately.

It is important to note that the accuracy of the flow measurement using a venturi meter relies on proper installation, calibration, and accurate measurement of the pressure difference. Additionally, the flow conditions and fluid properties should be within the operating range specified for the particular venturi meter being used.

venturi meter formula

The flow rate through a venturi meter can be calculated using the Bernoulli’s equation and the conservation of mass. The most commonly used formula for calculating the flow rate through a venturi meter is the following:

Q = C * A * sqrt(2 * ΔP / ρ)

where:

Q is the volumetric flow rate (in m³/s or ft³/s),

C is the discharge coefficient (dimensionless), which accounts for the efficiency of the venturi meter,

A is the cross-sectional area of the throat (in m² or ft²),

ΔP is the pressure difference between the upstream and throat sections (in Pa or psi),

ρ is the density of the fluid (in kg/m³ or lb/ft³).

The discharge coefficient, C, is specific to each venturi meter design and is typically provided by the manufacturer or determined through calibration. It takes into account the shape, size, and other characteristics of the venturi meter.

It’s important to note that the above formula assumes incompressible, steady-state flow conditions and neglects frictional losses and other minor effects. Additionally, the units of measurement must be consistent in the formula for accurate results.

To ensure accurate flow rate calculations, it is recommended to refer to the specific venturi meter’s documentation or consult the manufacturer’s guidelines, as they may provide additional correction factors or considerations specific to their product.

venturi meter used to measure

Venturi meters are used to measure the flow rate of fluids, both liquids and gases, in various industries and applications.

venturi meter specifications

The venturi meter specifications you provided are as follows:

- Line Size: The venturi meter is available in a range of line sizes, starting from 100 mm and going up to 800 mm. This means it can be used in pipes with diameters within this size range.

- Accuracy: The accuracy of the venturi meter can vary depending on the specific design and manufacturing quality. The stated accuracy ranges from +/-0.25% to +/-3.0%. This means that the measured flow rate may deviate from the actual flow rate by a maximum of the specified percentage.

- Flow Coefficient: The flow coefficient, often denoted as “C,” is a dimensionless value that represents the efficiency of the venturi meter. In this case, the flow coefficient value is given as 0.98 for all ratios of diameter. This indicates that the venturi meter has a high efficiency in terms of accurately measuring the flow rate.

- Beta Ratios: The beta ratio represents the ratio of the throat diameter to the main pipe diameter. In this case, the venturi meter has two specified beta ratios: 0.3 and 0.75. This means that the throat diameter is 30% or 75% of the main pipe diameter, depending on the chosen configuration.

These specifications provide information about the size range, accuracy, flow coefficient, and beta ratios of the venturi meter. It’s important to note that these specifications may vary depending on the manufacturer and specific model of the venturi meter. Therefore, it is recommended to consult the manufacturer’s documentation or specifications for the particular venturi meter you are considering to ensure accuracy and compatibility with your application.

applications of venturi meter

Venturi meters have several applications across different industries. Some of the common applications of venturi meters include:

- Flow Measurement: It is widely used for measuring the flow rate of fluids, both liquids, and gases. They are commonly employed in water supply systems, irrigation systems, wastewater treatment plants, and industrial processes where accurate flow measurement is essential.

- Water Distribution Systems: In water distribution systems, venturi meters are used to monitor and control the flow of water. They help in managing water resources, detecting leaks, and ensuring an equitable distribution of water.

- Oil and Gas Industry: It play a crucial role in the oil and gas industry for measuring the flow rates of various fluids, such as crude oil, natural gas, and petroleum products. They are used in pipelines, refineries, and well testing operations.

- HVAC Systems: It is utilized in heating, ventilation, and air conditioning (HVAC) systems to measure the flow rates of air and ensure proper airflow in buildings. This helps in maintaining comfortable indoor environments and optimizing energy efficiency.

- Chemical Processing: In chemical plants and manufacturing facilities, venturi meters are employed to measure the flow rates of different chemicals and fluids. They are essential for process control, monitoring, and optimization.

- Environmental Monitoring: It find applications in environmental monitoring and research studies. They are used to measure the flow rates of water in rivers, streams, and canals, providing valuable data for water resource management and ecological studies.

- Laboratory and Research: It is used in laboratory settings and research experiments where precise flow measurement is required. They are often used in experimental setups, test rigs, and calibration processes.

Overall, the versatility, accuracy, and reliability of venturi meters make them widely used in numerous industries and applications where flow measurement is critical for efficient and safe operations.

advantages of venturi meter

Venturi meters offer several advantages that make them popular in flow measurement applications. Some of the key advantages of venturi meters are:

- Low Pressure Drop: It has a streamlined design that minimizes pressure drop across the meter. This means that the energy required to push the fluid through the meter is significantly lower compared to other flow measurement devices, resulting in reduced energy consumption and cost savings.

- High Accuracy: It provide accurate flow measurement when properly calibrated and installed. The design of the venturi meter ensures a stable and predictable flow profile, resulting in reliable and precise measurements. They can achieve accuracies within a few percentage points, depending on the specific design and operating conditions.

- Wide Flow Range: It has a wide turndown ratio, which means they can measure a broad range of flow rates accurately. This versatility makes them suitable for applications where the flow rates may vary significantly over time or across different operating conditions.

- Minimal Maintenance: It has a simple design with no moving parts, making them relatively low maintenance devices. They are less prone to clogging or fouling compared to other flow meters, reducing the need for regular cleaning or replacement.

- Wide Range of Fluid Compatibility: It can handle a wide range of fluid types, including liquids and gases. They are compatible with various chemicals, fuels, oils, and water, making them suitable for diverse industrial applications.

- Cost-Effective: These are generally more cost-effective compared to some other types of flow meters. Their simpler construction and lower pressure drop result in lower initial and operational costs, making them an economical choice for many flow measurement applications.

- Durability: These are typically made of robust materials such as stainless steel or high-quality plastics, ensuring durability and long service life. They can withstand high-pressure environments and harsh operating conditions, making them suitable for challenging industrial settings.

It is important to note that while venturi meters offer many advantages, their accuracy and performance can be affected by factors such as proper installation, calibration, and maintaining a clean and debris-free flow path. Regular inspection and maintenance are necessary to ensure optimal performance and accurate measurements.

disadvantages of venturi meter

While venturi meters offer several advantages, they also have a few limitations and disadvantages. Some of the key disadvantages of venturi meters include:

- Installation and Space Requirements: Proper installation of a venturi meter requires specific guidelines and expertise. It is essential to ensure correct positioning, alignment, and distance from disturbances in the flow to achieve accurate measurements. Additionally, venturi meters require a sufficient length of straight pipe both upstream and downstream of the meter to allow for adequate flow conditioning, which may not always be feasible in constrained spaces.

- Limited Turndown Ratio at Low Flow Rates: While venturi meters have a wide turndown ratio, their accuracy decreases at very low flow rates. They may not provide accurate measurements in applications that require precise flow monitoring and control at extremely low flow rates.

- Sensitivity to Fluid Properties: These are sensitive to changes in fluid properties, such as temperature, density, viscosity, and composition. Variations in these properties can affect the accuracy of the flow measurement. Some venturi meters may require additional corrections or calibration to compensate for such variations.

- Potential for Flow Disturbances: In certain flow conditions, such as high velocities or turbulent flow, venturi meters can cause flow disturbances or pressure fluctuations. This can lead to inaccuracies in flow measurement or affect the overall system performance. Additional measures, such as flow straighteners or downstream pressure recovery devices, may be required to mitigate these disturbances.

- Limited Application to Non-Circular Pipes: These are primarily designed for use in circular pipe configurations. They may not be suitable for non-circular pipes or irregular flow geometries, requiring alternative flow measurement devices to be used in such cases.

- Potential for Clogging and Fouling: While venturi meters are generally less prone to clogging or fouling compared to some other flow meters, they can still be susceptible to debris accumulation or buildup over time. Regular inspection and maintenance are necessary to ensure proper functionality and accuracy.

- Relatively Higher Initial Cost: While venturi meters are cost-effective compared to some other flow measurement devices, their initial cost may be higher than simpler flow meters such as orifice plates or flow nozzles. This initial investment may be a consideration in budget-sensitive applications.

Despite these disadvantages, venturi meters remain widely used in many industries due to their overall accuracy, reliability, and versatility in flow measurement applications. It is important to carefully assess the specific requirements and limitations of a given application before selecting a flow meter, including considering alternative options if necessary.

Reference : https://whatispiping.com/venturi-meter/