In this article, we will explore the different parts of transformer and their functions. We will provide clear explanations and include pictures to help you visualise each component.

what is Transformer ?

A transformer is an electrical device that transfers electrical energy between two or more circuits through electromagnetic induction. It consists of a primary coil and a secondary coil wound around a core made of magnetic material. When an alternating current (AC) flows through the primary coil, it creates a changing magnetic field that induces a voltage in the secondary coil. Transformers are used to increase or decrease voltage levels in power distribution, enabling efficient transmission of electricity over long distances and facilitating the operation of various electrical devices.

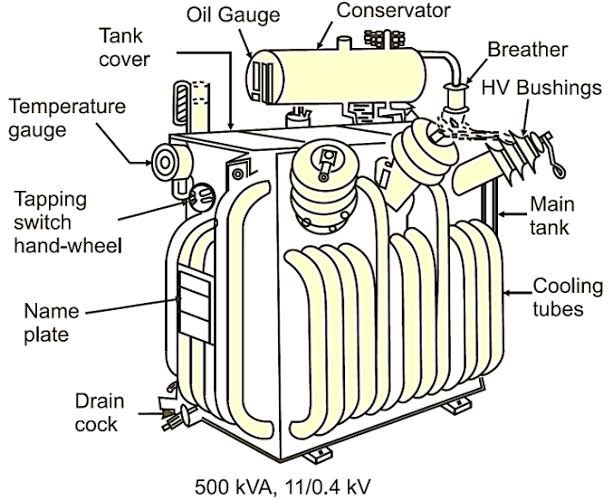

The parts of a transformer are the various components that work together to enable the efficient transfer of electrical energy. These parts include the core, windings, insulation, transformer oil, terminals and bushings, cooling system (radiators and fans), tap changer, breather, and various protective devices such as the Buchholz relay and explosion vent. Each part has a specific function and plays a crucial role in ensuring the transformer’s proper operation and safety. Understanding the different parts of a transformer is essential for maintaining and troubleshooting these devices effectively.

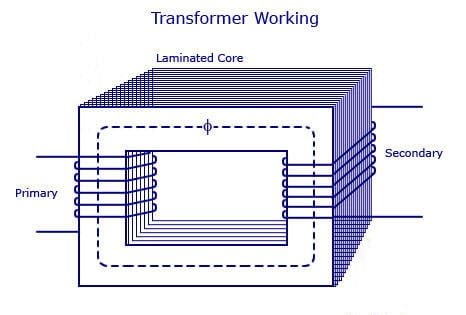

working principle of transformer

The working principle of a transformer is based on electromagnetic induction. When an alternating current (AC) flows through the primary winding, it generates a changing magnetic field. This changing magnetic field induces a voltage in the secondary winding through electromagnetic induction.

The magnitude of the induced voltage depends on the ratio of the number of turns in the windings. Transformers can step up or step down the voltage by adjusting the number of turns in the primary and secondary windings. This principle allows for the efficient transfer of electrical energy from one circuit to another without direct electrical connection, enabling voltage transformation in power transmission and distribution systems.

Must read: Fleming’s Right hand rule

parts of transformer

All parts of transformer are following:-

- Core

- Winding

- Tank

- Insulation

- Transformer oil

- Terminals and bushings

- Breather

- Tap changer

- Radiators and fans

- Cooling tubes

- Buchholz relay

- Explosion vent

- Oil conservator

- Temperature gauge

1.Core

Core is the centre of transformer which is used for constructions of transformer.The core provides a low reluctance path for electromagnetic flux and supports the primary and secondary windings. It is constructed by stacking thin sheets of high-grade grain-oriented steel separated by thin insulating material. To reduce hysteresis and eddy currents, the carbon content of the core steel is kept below 0.1%. Eddy currents can be reduced by alloying with silicon.

The figure above depicts a typical three-phase transformer core. Each limb carries the primary and secondary winding of each phase. The yokes are magnetically coupled to the limbs. Core constructions are classified into two types: core and shell. The windings are surrounded by the core in shell-type construction, as shown below;

2. winding

Winding of transformer is current carrying conductors which is wound around the core which forms the electrical circuit of transformer. or, we can say that Transformer winding refers to the arrangement of conductive materials, typically copper or aluminum, to form coils in a transformer. These coils play a crucial role in the conversion and transmission of electrical energy between different voltage levels.

Winding consists of several number of turns of copper conductors that is bundled together and connected in series. You can see in figure.

The type and arrangement of windings used in transformers depend on several factors such as the current rating, short circuit strength, temperature rise, impedance, and surge voltages.

Transformers have two main types of windings: the primary winding and the secondary winding. The primary winding is connected to the input voltage source, while the secondary winding is connected to the output circuit. These windings are made up of conductive materials, like copper or aluminum, which form coils.

The primary and secondary winding of a transformer are divided into two parts: the high voltage (HV) winding and the low voltage (LV) winding. The high-voltage winding handles higher voltage levels, while the low-voltage winding deals with lower voltage levels. The choice between high-voltage and low-voltage windings depends on the specific voltage range required for each winding. The number of turns in the winding and its ability to carry current help determine whether it should be used for the high voltage or low voltage side of the transformer.

Functions

The main function of windings is to carry current and produce working magnetic flux and induce mutual EMF for transformer action.

Tank

The tank of a transformer serves as a protective enclosure that houses and safeguards the core, windings, and other internal components. It plays a crucial role in ensuring the safe and reliable operation of the transformer.

functions

The tank of a transformer provides structural support protects the core and the windings from the external environment, contains the insulating oil, facilitates pressure relief, enables oil level monitoring, offers corrosion resistance, allows for maintenance accessibility, and provides grounding provisions. These features ensure the safe and efficient operation of the transformer, extending its lifespan and protecting it from external environmental influences.

Insulation

Insulation in a transformer refers to the materials and techniques used to electrically isolate different components and prevent the flow of current between them.

Insulation is extremely important in transformers because if it fails, it can cause serious damage. Insulation is needed in multiple places within the transformer: between the windings and the core, between the windings themselves, between each turn of the winding, and between any parts that carry electrical current and the tank. The insulating materials used should have high dielectric strength, good mechanical properties, and the ability to withstand high temperatures. Examples of insulation materials used in transformers include synthetic materials, paper, and cotton.

Function

Insulation in a transformer has various functions, including electrical isolation, voltage withstand capability, prevention of short circuits, thermal insulation, protection against moisture and contaminants, mechanical support, and electrical stress control.

Transformer oil

Transformer oil is used to insulate and cool the core and coil assembly of a transformer. It is important that the transformer’s core and windings are fully immersed in the oil. The oil used in transformers is usually mineral oil, which contains hydrocarbons.

The primary purpose of transformer oil is to provide extra insulation between the different parts of the transformer. It helps prevent electrical current from flowing between the conductors, ensuring safe and efficient operation. Additionally, the oil helps in dissipating heat generated during transformer operation, keeping the temperature within acceptable limits.

Transformer oil is also useful in detecting faults in oil-immersed transformers. It has a flashpoint of 310°C, meaning it can withstand high temperatures without catching fire easily. The oil’s relative permeability is 2.7°C, which means it has good magnetic properties. Furthermore, its density is 0.96 kg/cm3.

functions

It’s function is to provide the insulation between windings as well as cooling due to its chemical properties and very good dielectric strength.

terminals and Bushing

Terminals: Terminals in a transformer are the connection points where external electrical conductors are connected. These conductors are used to supply and distribute electrical power to and from the transformer. The terminals provide a secure and reliable connection for the incoming and outgoing electrical wires.

Bushings are insulating devices used to provide a passage for electrical conductors through the walls of the transformer tank. They serve as a connection point between the internal windings and the external electrical system. Bushings help maintain the electrical insulation and prevent leakage of current or oil from the transformer.

breather

A breather is an important component in a transformer that helps to maintain the quality of the insulating oil by preventing moisture from entering the transformer.

It is attached to the transformer’s conservator tank, which is a reservoir that holds the transformer oil. The breather consists of a container filled with a desiccant material, usually silica gel, which has the ability to absorb moisture from the air.

The main function of the breather is to protect the transformer oil from coming into contact with moisture or humidity in the atmosphere. Moisture is harmful to the transformer oil as it can degrade its insulation properties and reduce the overall effectiveness of the transformer.

When air enters the transformer during the cooling process or due to changes in volume caused by temperature fluctuations, it passes through the breather. As the air passes through the silica gel inside the breather, the desiccant material absorbs the moisture present in the air, ensuring that only dry air enters the transformer.

By preventing moisture from entering the transformer, the breather helps to maintain the dielectric strength and insulation properties of the transformer oil. This, in turn, helps to ensure the efficient and reliable operation of the transformer.

Periodically, the silica gel in the breather needs to be regenerated or replaced to maintain its effectiveness in absorbing moisture. This is typically done by drying the silica gel or replacing it with fresh desiccant material.

Tap Changer

A tap changer is an important component in a transformer that allows for the adjustment of the transformer’s output voltage to match varying load or voltage conditions. Here’s a simple explanation;

A tap changer is a mechanism or device installed in the transformer that adjust the transformer’s output voltage to much varying load or conditions of load by adjustment of the number of turns in the transformer winding. By changing the number of turns, the voltage ratio of the transformer can be modified, which in turn adjusts the output voltage.

here are two common types of tap changers: on-load tap changers (OLTC) and off-circuit tap changers (OCTC). On-load tap changers allow for voltage adjustment while the transformer is energized and under load, while off-circuit tap changers require the transformer to be de-energized for the adjustment to take place.

Radiators and Fans

Radiators and fans are parts of transformer which help in dissipate heat generated during transformer operation.

Radiators: Radiators in a transformer are external heat exchangers designed to transfer heat from the transformer’s core and windings to the surrounding environment. They are typically installed on the sides or top of the transformer tank and consist of a series of metal fins or tubes that provide a large surface area for heat dissipation.

Fans: Fans are often used in conjunction with radiators to enhance the cooling process in transformers. They are typically electrically driven and are installed behind or between the radiator fins. The fans help to increase the airflow over the radiators, thus improving heat transfer and cooling efficiency.

Cooling Tubes

The cooling tubes allow the transformer oil to flow through them, either naturally or with the help of a pump. When the oil gets hot, it naturally rises to the top of the transformer and flows through the cooling tubes, where it cools down. This is called natural circulation.

In some cases, especially when there is a need for faster cooling, an external pump is used to force the oil to circulate between the hot and cold areas of the transformer. This is called forced circulation. The pump helps to move the oil through the cooling tubes more quickly, enhancing the cooling process.

Explosion Vent

An explosion vent is a safety feature in transformers that prevents excessive pressure buildup. It automatically releases pressure during internal faults, reducing the risk of explosions. Installed on the transformer tank or cover, the vent opens or ruptures at a predetermined pressure threshold. This controlled release protects the transformer from catastrophic damage and safeguards personnel and nearby equipment. Regular inspection and maintenance ensure the vent’s proper functionality.

Buchholz Relay

The Buchholz relay is an important component in large oil-immersed transformers above 500kVA. It is designed to detect faults that happen within the oil-filled parts of the transformer.

When a short circuit occurs in the transformer, it generates heat that can break down the oil into gases like hydrogen, carbon monoxide, and methane. These gases slowly move towards the conservator tank through a pipe. The Buchholz relay, located on the pipe connecting the conservator tank and the main tank, senses these gases and triggers alarm and trip circuits.

The trip circuit opens the circuit breaker that supplies electricity to the primary winding of the transformer, stopping the flow of current. This helps prevent further damage and ensures safety.

Oil Conservator

The conservator tank in a transformer is a cylindrical tank located on top of the main tank. Its main purpose is to provide extra space for the transformer oil to expand when it gets heated. When the transformer is in use or when the temperature rises, the volume of oil inside the transformer increases. The conservator tank allows for this expansion by acting as a reservoir for the transformer oil. It ensures that there is enough room for the expanded oil and helps maintain the proper level of insulating oil in the transformer.

temperature gauge

The temperature gauge is a device that measures and displays the temperature inside the transformer. It is typically connected to a sensor or a thermometer placed in critical locations such as the winding, core, or oil.

Source :- Wikipedia

good