what is snap fit ?

A snap fit is a method to put together things made of flexible material, usually plastic, by pushing their interlocking parts together. It’s like when you join puzzle pieces or snap two Lego bricks together. This method is commonly used in manufacturing to assemble products quickly and securely without needing any tools or extra parts like screws.

snap fit symbol

- y = permissible deflection

- b = width at root

- c = center of gravity (i.e., distance between outer fiber and neutral fiber)

- E as absolute value = percentage/100

- E = permissible strain in the outer fiber at the root

- l = length of arm

- K = geometric factor

- h = thickness at root

- Es = secant modulus

- P = permissible deflection force

- Z = section modulus

- Z = I c; where I = axial moment of inertia

Must Read : Limits Fits and Tolerances

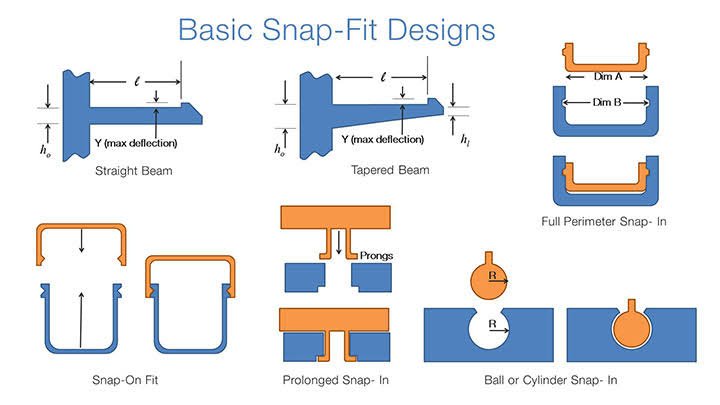

types of snap fit

There are several types of snap joints commonly used in product design and manufacturing. Here are a few examples:

- Cantilever Snap Joint: In a cantilever snap joint, one component has a flexible cantilever beam that bends or deflects to allow for insertion or removal of the mating component. The beam acts as a spring, providing the necessary retention force to keep the components securely connected.

- Torsion Snap Joint: A torsion snap joint involves twisting or rotating one component relative to another to achieve engagement or disengagement. The torsional force provides the required retention and allows for easy assembly and disassembly of the components.

- Annular Snap Joint: An annular snap joint consists of a circular or ring-shaped feature on one component that fits into a corresponding groove or recess on the mating component. The circular shape provides a secure and reliable connection, and the snap engagement occurs when the ring snaps into the groove.

- Snap-Fit Tab Joint: In a snap-fit tab joint, one component has a tab or protrusion, while the other component has a corresponding slot or recess. The tab is inserted into the slot, and the snap fit occurs when the tab snaps securely into place, holding the components together.

- Snap-Fit Bead Joint: A snap-fit bead joint involves using a bead or ridge on one component that snaps into a channel or groove on the mating component. The bead slides into the channel, and the snap fit occurs when it reaches the desired position, creating a secure connection.

- Snap-Fit Snap-Latch Joint: A snap-fit snap-latch joint consists of a latch or hook feature on one component that engages with a corresponding latch or hook feature on the mating component. The snap fit occurs when the latch and hook securely interlock, holding the components together.

- L-Shaped Snap Joints: L-shaped snap joints feature an L-shaped design, with one component having an L-shaped projection or tab, and the other component having a corresponding L-shaped slot or receptacle. The tab is inserted into the slot, and the snap fit occurs when the tab securely engages with the slot, creating a strong connection between the components.

- U-Shaped Snap Joints: U-shaped snap joints involve a U-shaped feature on one component that fits into a U-shaped groove or recess on the mating component. The U-shaped element acts as a spring, providing the necessary flexibility to allow for insertion or removal of the components. The snap fit occurs when the U-shaped feature snaps securely into the groove, ensuring a reliable connection.

These are just a few examples of the types of snap joints used in various industries. The selection of a specific snap joint type depends on the application requirements, desired retention force, ease of assembly and disassembly, and other design considerations.

Common snap-fit design problems

Certainly! Here are common snap-fit design problems along with a brief description:

- Insufficient Engagement: This occurs when the snap-fit components do not fully engage, resulting in a weak or loose connection. It can be addressed by ensuring sufficient depth, width, and engagement length of the interlocking features.

- Excessive Engagement Force: Excessive force required for assembly can make it difficult or uncomfortable for users. Designers should aim for an appropriate balance of retention force while ensuring ease of assembly and disassembly.

- Insufficient Retention Force: If the snap fit does not provide enough retention force, the components may separate unintentionally. Optimizing the geometry and material properties can help increase the retention force.

- Excessive Deformation: Excessive deformation of snap-fit components can lead to permanent damage, compromising the integrity of the connection. Proper material selection and design considerations can help prevent excessive deformation.

- Fatigue Failure: Repeated assembly and disassembly cycles can lead to fatigue failure of snap-fit components, causing them to break or lose their retention force. Designers should consider fatigue-resistant design techniques, material selection, and stress distribution to mitigate this problem.

- Environmental Impact: Snap-fit designs should consider the environmental impact, such as the choice of materials and end-of-life recyclability. Using sustainable materials and designing for easy disassembly and recycling can reduce the environmental footprint.

- Cost: Snap-fit designs should balance performance requirements with cost considerations. Complex snap-fit designs or expensive materials can significantly increase production costs, so it’s important to optimize the design for cost-effectiveness without compromising functionality.

Addressing these common snap-fit design problems involves careful consideration of factors such as material selection, geometry optimization, proper tolerancing, prototyping, and testing. Iterative design improvements and validation can help ensure the functionality, reliability, and cost-effectiveness of snap-fit connections.

Common Snap Fit Design Problems and Best Practices

Here are some common snap fit design problems that engineers may encounter, along with best practices to address them:

- Stress Concentrations: Sharp corners in the design of cantilever snap joints can lead to stress concentrations at the root of the joint, increasing the risk of failure. To mitigate this issue, designers should consider adding fillets or radii to distribute stress more evenly and reduce the likelihood of shearing off.

- Creep: Plastics and thermoplastics used in snap fit designs are prone to creep, which is a gradual deformation under sustained stress. This can compromise the integrity of the connection over time. Designers should choose materials with low creep tendencies or consider reinforcing the snap fit areas to minimize the effects of creep.

- Repetitive or Fatigue Loading Failure: Snap fits subjected to repeated assembly and disassembly cycles may experience fatigue failure, especially at high loading frequencies. Designers can address this by optimizing the snap fit geometry, selecting materials with good fatigue resistance, and performing thorough testing to ensure durability under cyclic loading conditions.

- Tolerance Issues: Tolerance problems can occur when gaps between mating components are not properly accounted for in the design. This can lead to difficulties in assembly or improper fit between components. Designers should carefully consider manufacturing tolerances and ensure that components are designed with appropriate clearances and fits to accommodate expected variations.

By addressing these common snap fit design problems, engineers can enhance the reliability, durability, and performance of snap fit connections. It is important to consider the specific application requirements, material properties, manufacturing processes, and anticipated usage conditions when designing snap fits to ensure optimal functionality.

application of snap fit

Snap fits are used to securely attach and join flexible parts together to form a final product. This assembly method is particularly suited for connecting plastic components. By snapping the interlocking features of the parts together, a tight and stable connection is achieved without the need for additional tools, adhesives, or fasteners. Snap fits offer a convenient and efficient way to assemble products, and they find applications in industries such as consumer electronics, automotive, packaging, toys, furniture, and more.

Various applications across different industries. Here are some common examples:

- Consumer Electronics: Snap fits are widely used in consumer electronics such as smartphones, tablets, and laptops. They help in assembling the casing, battery compartments, and other components quickly and securely.

- Automotive Industry: Snap fits are employed in automotive manufacturing for interior and exterior components. They are used in assembling dashboard components, door panels, trim pieces, and various other parts.

- Packaging: Snap fits are commonly used in packaging materials such as plastic containers, clamshell packaging, and blister packs. They provide a secure closure without the need for additional adhesives or fasteners.

- Medical Devices: Snap fits find applications in medical device manufacturing. They are used for assembling components of medical devices, such as inhalers, insulin pens, and surgical instruments.

- Toys and Games: Snap fits are extensively used in the toy and game industry. They allow for quick assembly of plastic parts in products like building blocks, action figures, and board games.

- Electrical and Electronic Enclosures: Snap fits are employed in the assembly of electrical and electronic enclosures. They help in joining components like covers, panels, and access doors securely.

- Furniture and Home Appliances: Snap fits can be found in the assembly of furniture and home appliances. They are used for joining plastic or flexible parts in products like cabinets, drawers, and appliance housings.

These are just a few examples of the many applications of snap fits. Their versatility, ease of assembly, and cost-effectiveness make them a popular choice for joining flexible components in a wide range of industries.

advantages of snap fit

Snap fits offer several advantages in product design and manufacturing. Here are some key advantages of using snap fits:

- Quick and Easy Assembly: It allow for fast and straightforward assembly of components. The interlocking features can be easily engaged by applying pressure, eliminating the need for complex tools or time-consuming processes. This leads to increased production efficiency and reduced assembly time.

- Cost-Effective: It can reduce manufacturing costs by eliminating the need for additional fasteners such as screws, bolts, or adhesives. This not only reduces material and labor costs but also simplifies the assembly process, resulting in overall cost savings.

- Disassembly and Maintenance: It enable easy disassembly of components, which is beneficial for maintenance, repair, or product upgrades. When a product requires servicing or replacement of parts, snap fits allow for quick and hassle-free disassembly, reducing downtime and increasing convenience.

- Design Flexibility: It offer design flexibility, allowing for the creation of intricate and complex shapes. The interlocking features can be designed to accommodate various geometries, providing versatility in product design. This flexibility opens up possibilities for innovative and visually appealing designs.

- Secure Connection: When properly designed, snap fits can provide a secure and robust connection between components. The interlocking features ensure that the parts stay firmly together during use, even under vibrations or other external forces. This enhances the overall stability and durability of the assembled product.

- Recyclability: It contribute to environmentally friendly practices in product design. They facilitate easy disassembly of components, making it easier to separate different materials for recycling purposes. This promotes sustainability and reduces the environmental impact of the product.

- Aesthetics and User Experience: It can enhance the aesthetics of a product by providing seamless and clean lines without visible fasteners. Additionally, snap fits can improve the user experience by offering user-friendly assembly and disassembly, allowing consumers to easily interact with the product.

These advantages make snap fits a popular choice in various industries, offering efficient assembly, cost savings, and design flexibility while maintaining secure connections between components.

disadvantages of snap fit

While snap fits offer many advantages, there are also some potential disadvantages to consider. Here are a few disadvantages associated with snap fits:

- Limited Load-Bearing Capacity: It may have limitations when it comes to bearing heavy loads or withstanding significant forces. The interlocking features may not provide the same strength as other fastening methods, such as screws or welding. It’s important to carefully evaluate the application’s requirements and ensure the snap fit design can handle the expected loads.

- Material Limitations: It is most commonly used with plastic components. However, certain types of plastics may not be suitable for snap fit applications due to their low flexibility or brittleness. It’s crucial to choose materials with appropriate mechanical properties to ensure the snap fit’s durability and longevity.

- Tolerance Sensitivity: Snap fits are sensitive to manufacturing tolerances. Even slight variations in component dimensions or tolerances can affect the fit and functionality of the snap fit. This requires precise control over manufacturing processes to ensure consistent and reliable snap fit connections.

- Design Complexity: Designing effective snap fits can be challenging, especially for complex geometries or intricate interlocking features. It requires careful consideration of factors such as material selection, geometry, and clearances. Iterative prototyping and testing may be necessary to optimize the snap fit design for desired performance.

- Limited Disassembly and Repair Options: While snap fits allow for easy assembly, disassembly may not always be as straightforward. In some cases, disassembling snap fit components without causing damage or deformation can be challenging. This limitation may affect repairability or component replacement options.

- Noise and Wear: Snap fits can generate noise or wear over time, especially if the interlocking features experience repeated assembly and disassembly cycles. This can be a concern in applications where noise or wear needs to be minimized, such as in certain consumer products.

- Aesthetics and Visible Seams: Depending on the design and placement of snap fits, they may create visible seams or parting lines on the assembled product. This can affect the aesthetics, especially in applications where a seamless appearance is desired.

Despite these potential disadvantages, snap fits remain a popular and widely used method for joining components due to their numerous advantages. It’s essential to carefully consider the specific application requirements and design constraints when deciding whether to use snap fits or explore alternative fastening methods.

Reference : https://en.wikipedia.org/wiki/Snap-fit