What is a Duckbill Check Valve

A duckbill check valve is a one-way valve that allows fluid or gas to flow in only one direction. Its name is derived from its shape, which resembles the beak of a duck. Unlike traditional check valves with moving parts, such as swing check valves or spring-loaded check valves, the duckbill check valve operates without mechanical components. Instead, it utilizes a flexible elastomeric material, typically silicone or rubber, to create a valve that opens and closes in response to fluid or gas pressure.

Duck Bill Check Valve Parts

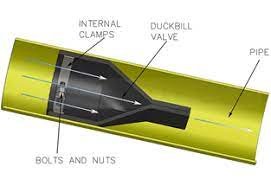

Duckbill check valves are relatively simple in design and consist of a few essential parts that work together to control the flow of fluids or gases in one direction while preventing backflow. The key parts of a typical duckbill check valve include:

- Body or Housing: The body or housing of the duckbill check valve serves as the outer casing that contains and supports the other components. It is typically made of materials such as plastic, metal, or elastomers, depending on the application’s requirements.

- Elastomeric Diaphragm: The heart of the duckbill check valve is the elastomeric diaphragm, which is usually made from materials like silicone or rubber. This diaphragm is responsible for creating the one-way seal. Its unique shape, resembling a duck’s bill, gives the valve its name. The diaphragm is flexible and designed to flex open when there is sufficient pressure on the inlet side and return to its closed position when the pressure equalizes or reverses.

- Inlet/Outlet Ports: These are the openings in the body of the valve through which fluids or gases enter and exit. The inlet port is where the medium enters, and the outlet port is where it exits.

- Retention or Flange Ring: Some duck bill check valves have a retention or flange ring at the inlet port. This ring helps secure the elastomeric diaphragm in place and ensures a proper seal when the valve is in the closed position.

- Clamp or Fasteners (Optional): In some cases, duck bill check valves may include clamps, fasteners, or other securing mechanisms to hold the diaphragm in place within the valve body. This is especially common in high-pressure or critical applications.

- Connection or Fittings (Optional): Depending on the application, duckbill check valves may have various types of connections or fittings at the inlet and outlet ports, such as threaded connections, flanges, or barbed connections, to facilitate installation and integration into the system.

These are the fundamental parts of a duckbill check valve. The valve’s operation relies on the flexibility of the elastomeric diaphragm to open and close in response to fluid or gas pressure, allowing flow in one direction while preventing backflow. The specific design and materials used can vary based on the valve’s intended application and the manufacturer’s specifications.

How does Duck bill check valve works

A duck bill check valve is a type of one-way valve that operates without any mechanical components, such as springs or hinges. Instead, it relies on the unique design of a flexible elastomeric diaphragm to control the flow of fluids or gases. Here’s how a duckbill check valve works:

- Initial Closed Position: In its default or initial state, a duckbill check valve is closed. The elastomeric diaphragm, which has a shape resembling a duck’s bill or beak, is at rest and seals the inlet port. This position prevents any fluid or gas from flowing backward.

- Pressure Differential: When there is a pressure differential between the inlet and outlet ports of the valve, meaning the pressure on the inlet side is greater than on the outlet side, the valve begins to operate. The greater pressure on the inlet side forces the elastomeric diaphragm to flex open.

- Diaphragm Flexes Open: As the pressure on the inlet side increases, it exerts force on the flexible diaphragm, causing it to flex outward or open. This action allows the fluid or gas to flow through the valve from the inlet to the outlet.

- Flow Direction Control: The direction of flow is controlled by the valve’s design and orientation. In a duckbill check valve, the natural shape of the diaphragm ensures that it opens only when there is a pressure difference in the intended flow direction, preventing backflow.

- Equalizing Pressure: Once the pressure on the inlet and outlet sides of the valve equalizes or reverses, the flexible diaphragm returns to its default, closed position. This immediate response ensures that the valve seals effectively, preventing backflow of the fluid or gas.

- Silent Operation: One of the advantages of duckbill check valves is their silent operation. Because they don’t have any mechanical parts that slam or chatter when the valve closes, they operate quietly, making them suitable for applications where noise reduction is important.

It’s important to note that duckbill check valves are typically designed to have a low cracking pressure, meaning they open with minimal pressure differential. This feature allows them to be used in applications with low-pressure systems or situations where only a slight pressure change is available to open the valve.

Overall, duckbill check valves provide reliable one-way flow control without the need for moving parts, making them a durable and efficient choice in a wide range of applications where backflow prevention is critical.

Duck bill Check valve working

A duck bill check valve operates on a simple yet effective principle, relying on the unique design of a flexible elastomeric diaphragm to control the flow of fluids or gases. In its default position, this valve remains closed, thanks to the diaphragm’s shape resembling a duck’s bill, which seals the inlet port and prevents any reverse flow. However, when there’s a pressure differential between the inlet and outlet ports—meaning the inlet side has greater pressure—the valve responds.

The higher pressure on the inlet side forces the elastomeric diaphragm to flex open, enabling the fluid or gas to flow from the inlet to the outlet. Crucially, the diaphragm’s design ensures it opens only when there’s a pressure difference in the desired flow direction, effectively preventing backflow.

Once the pressure Equalizes or reverses, the diaphragm promptly returns to its closed position, making duckbill check valves dependable and silent in their operation. This simplicity, reliability, and quiet operation make them an excellent choice for various applications, from medical devices to wastewater treatment systems, where backflow prevention is essential.

Signs of damage Duckbill check valve

Detecting signs of damage in equipment, machinery, or structures is crucial for ensuring safety, preventing accidents, and avoiding costly repairs or replacements. Signs of damage can vary depending on the specific item or system, but there are some common indicators to watch for:

- Visible Cracks or Fractures: Cracks, fractures, or fissures in materials, such as metal, concrete, or wood, are clear signs of structural damage. These can weaken the integrity of the object and may lead to catastrophic failure if not addressed.

- Corrosion: Rust, oxidation, or corrosion on metal surfaces can signal structural weakness. It’s important to regularly inspect metal components for signs of corrosion, especially in outdoor or corrosive environments.

- Leakage or Fluid Drips: Leaking fluids, such as oil, coolant, or hydraulic fluid, are indicative of damage to pipes, hoses, seals, or gaskets. Addressing leaks promptly can prevent further damage and environmental contamination.

- Unusual Sounds or Noises: Unusual noises, like grinding, squealing, or knocking, coming from machinery or equipment may indicate mechanical damage or malfunction. These sounds can be early warning signs of impending failure.

- Reduced Performance: A noticeable decrease in performance, efficiency, or output in machines or systems may be a sign of damage or wear and tear. Performance monitoring can help detect issues early.

- Vibrations or Unsteadiness: Excessive vibrations or instability in machinery or structures may indicate misalignment, loose components, or structural damage.

- Odors or Unusual Smells: Strange odors, such as burning or electrical smells, can indicate overheating or electrical problems, potentially leading to damage or fire hazards.

- Warning Lights or Alarms: Modern equipment often includes warning lights or alarms that activate when certain parameters are out of range. Ignoring these indicators can lead to further damage or accidents.

- Visible Wear and Tear: Obvious signs of wear, such as worn-out belts, damaged hoses, or eroded surfaces, should be addressed promptly to prevent further deterioration.

- Discoloration or Stains: Discoloration, stains, or discoloration on surfaces can indicate chemical damage, leaks, or contamination.

- Loose or Missing Fasteners: Loose bolts, nuts, screws, or other fasteners can compromise the integrity of structures or machinery. Missing fasteners should be replaced immediately.

- Excessive Heat: Unusually hot surfaces or components can indicate overheating, which can lead to damage or malfunction.

- Crushing, Buckling, or Warping: Signs of deformation or warping in structures or equipment can be clear indicators of damage.

- Irregularities in Electrical Systems: In electrical systems, flickering lights, circuit breaker trips, or damaged wiring can signal electrical damage.

- Excessive Heat or Smoke: The presence of heat, smoke, or visible flames is an obvious and urgent sign of damage or malfunction, often related to electrical or fire hazards.

Regular inspection, maintenance, and adherence to manufacturer’s guidelines can help identify signs of damage early, allowing for timely repairs and minimizing risks associated with equipment failure or structural damage.

Applications of Duckbill Check Valves

Duckbill check valves are versatile components used in a wide range of applications across various industries due to their unique design and effectiveness in preventing backflow. Here are some common applications of duckbill check valves:

- Medical Devices: Duckbill check valves are crucial components in medical devices such as infusion pumps, ventilators, and catheters. They ensure the controlled flow of fluids and gases in applications like intravenous drug delivery and respiratory therapy.

- Water and Wastewater Treatment: In sewage systems, stormwater management, and water treatment plants, duckbill check valves help maintain the one-way flow of water and prevent backflow, ensuring the efficient operation of these systems.

- Automotive Industry: Duckbill check valves are used in various automotive systems, including fuel systems and emission control. They help regulate the flow of fuel, exhaust gases, and fluids in vehicles.

- Aerospace: Aerospace applications rely on duckbill check valves for their ability to control the flow of critical fluids such as fuel and hydraulic fluids in aircraft and spacecraft.

- Industrial Manufacturing: Industries such as food and beverage production, chemical processing, and oil and gas exploration utilize duckbill check valves to manage fluid flow, ensuring process efficiency and safety.

- HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems incorporate duckbill check valves to control airflow, refrigerant flow, and fluid flow within the system, maintaining temperature and environmental control.

- Marine and Offshore: Duckbill check valves are employed in marine applications to prevent seawater from entering critical systems and to manage ballast water discharge in compliance with environmental regulations.

- Pumping Systems: They are used in various pumping systems to control the direction of fluid flow and to prevent backflow, ensuring the reliability and efficiency of pumps.

- Oil and Gas Industry: Duckbill check valves are utilized in oil and gas extraction and processing facilities to manage the flow of fluids, including crude oil, natural gas, and chemicals.

- Chemical Processing: Chemical plants often employ duckbill check valves to control the flow of corrosive or hazardous fluids, ensuring safety and efficiency in the production process.

- Pharmaceutical Industry: In pharmaceutical manufacturing, duckbill check valves help regulate the flow of fluids and gases during the production of medications and vaccines.

- Mining Operations: Duckbill check valves play a role in mining operations by controlling the flow of water, slurry, and other fluids in processes such as dewatering and material handling.

- Environmental Engineering: These valves are used in environmental engineering projects to prevent backflow in stormwater and wastewater management systems, helping protect water sources and ecosystems.

- Food and Beverage Industry: Duckbill check valves are used in food and beverage processing to control the flow of liquids, ensuring the quality and safety of food products.

- Pneumatic Systems: In pneumatic systems, duckbill check valves regulate the flow of compressed air or gases, allowing for controlled actuation and operation of pneumatic tools and equipment.

These diverse applications highlight the versatility and reliability of duckbill check valves, making them indispensable components in various industries where fluid control and backflow prevention are essential for safety, efficiency, and product quality.

advantages of duckbill check valve

Duckbill check valves offer several advantages that make them a preferred choice in many fluid control applications. Here are the key advantages of duckbill check valves:

- Reliable Backflow Prevention: Duckbill check valves provide excellent backflow prevention. Their one-way design ensures that fluids or gases flow in one direction only, preventing reverse flow and the associated contamination or damage.

- No Moving Parts: Unlike some other check valve types, duckbill check valves have no mechanical moving parts. This absence of moving components reduces the risk of wear, mechanical failure, and maintenance requirements, leading to increased reliability and longevity.

- Low Cracking Pressure: Duckbill check valves typically have a low cracking pressure, meaning they open and allow flow with minimal pressure differential. This feature makes them suitable for applications with low-pressure systems or situations where only a slight pressure change is available to open the valve.

- Silent Operation: Due to their design, duckbill check valves operate quietly. This feature is valuable in applications where noise reduction is essential, such as in medical devices, HVAC systems, and residential plumbing.

- Customizable Design: Manufacturers can customize duckbill check valves to meet specific application requirements. This includes tailoring the size, material, and performance characteristics of the valve to suit the intended use.

- Excellent Sealing: Duckbill check valves provide an effective seal when closed, preventing leakage or reverse flow. This sealing capability is especially important in applications where fluid containment or environmental protection is critical.

- Corrosion Resistance: Many duckbill check valves are made from elastomeric materials like silicone or rubber that offer resistance to corrosion and chemical attack. This property makes them suitable for use with various corrosive fluids.

- Wide Range of Materials: Duckbill check valves are available in a variety of materials to suit specific applications, including food-grade materials for the food and beverage industry, and medical-grade materials for healthcare applications.

- Ease of Installation: Installing duckbill check valves is generally straightforward, requiring minimal maintenance and adjustment once in place. This ease of installation contributes to their overall cost-effectiveness.

- Versatile Applications: Duckbill check valves find applications across a broad spectrum of industries, including medical, automotive, wastewater treatment, aerospace, and more. Their versatility makes them a versatile choice for various fluid control needs.

- Low Maintenance: Due to their simple design and absence of moving parts, duckbill check valves typically require minimal maintenance. This reduces downtime and maintenance costs in industrial processes and systems.

- Long Service Life: Duckbill check valves have a reputation for durability and a long service life. When properly selected and maintained, they can operate reliably for extended periods.

In summary, duckbill check valves offer a combination of reliability, versatility, and low maintenance that makes them suitable for a wide range of applications across diverse industries. Their ability to prevent backflow efficiently and quietly makes them a valuable choice for fluid control systems.

disadvantages of duckbill check valve

While duckbill check valves offer numerous advantages, they are not without their limitations and disadvantages. It’s important to consider these drawbacks when selecting a valve for a specific application. Here are some of the disadvantages associated with duckbill check valves:

- Limited Flow Rate: Duckbill check valves may have limitations in terms of flow rate, particularly in larger pipe sizes. Their design can restrict the flow of fluids, which may not be suitable for high-flow applications.

- Pressure Drop: These valves can introduce a pressure drop in the system, especially in applications where flow resistance is a concern. This pressure drop can reduce system efficiency.

- Backpressure Sensitivity: Duckbill check valves may be sensitive to backpressure. In some situations, a significant backpressure might be required to fully open the valve, which can limit their effectiveness in low-pressure systems.

- Material Compatibility: While many duckbill check valves are made from chemically resistant elastomeric materials, they may not be compatible with certain aggressive chemicals or extreme temperatures. Careful material selection is necessary for specific applications.

- Wear and Tear: Over time, the elastomeric material in duckbill check valves can experience wear, especially in high-frequency or high-flow applications. This wear can lead to reduced sealing effectiveness and eventually require valve replacement.

- Sensitivity to Debris: Duckbill check valves can be sensitive to debris or particulate matter in the fluid. Accumulated debris can hinder the proper functioning of the valve, potentially leading to blockages or reduced flow rates.

- Cost: In some cases, the initial cost of duckbill check valves may be higher than other types of check valves. While they may offer long-term cost savings due to reduced maintenance, the initial investment can be a consideration.

- Customization Complexity: Customizing duckbill check valves for specific applications may require more design and engineering effort compared to off-the-shelf solutions. This can lead to longer lead times and higher costs for tailored valves.

- Limited Temperature Range: Duckbill check valves may have limited temperature tolerance compared to some other valve types. Extreme temperatures can affect the elasticity and performance of the elastomeric materials used in these valves.

- Installation Orientation: Proper orientation during installation is crucial for the correct operation of duckbill check valves. Incorrect installation can lead to malfunction or reduced effectiveness.

- Flow Profile: Duckbill check valves may not be ideal for applications where a smooth, laminar flow profile is required. Their design can cause turbulence in the flow, which may not be suitable for some processes.

Thus, duckbill check valves have their advantages, but they are not universally applicable. It’s essential to carefully assess the specific requirements of your application, including flow rate, pressure, temperature, and fluid compatibility, to determine whether duckbill check valves are the right choice or if an alternative check valve type might be more suitable.

Frequently Asked Questions (FAQ) on Duckbill Check Valves

1.What is a duckbill check valve, and how does it work?

A duckbill check valve is a type of one-way valve that allows fluid or gas to flow in only one direction while preventing backflow. It operates using a flexible elastomeric diaphragm that opens in response to pressure on the inlet side and closes when the pressure equalizes or reverses.

2. Where are duckbill check valves commonly used?

Duckbill check valves find applications in various industries, including medical devices, wastewater treatment, automotive, aerospace, HVAC systems, and many more, where backflow prevention and one-way flow control are essential.

3. What are the advantages of duckbill check valves?

Duckbill check valves offer advantages such as reliability, simplicity (no moving parts), low cracking pressure, silent operation, customizable design, and durability. They are also resistant to corrosion and available in various materials for different applications.

4. Are there any limitations to using duckbill check valves?

Duckbill check valves may have limitations in terms of flow rate, sensitivity to debris, potential for pressure drop, and limited temperature ranges. Material compatibility and customization complexity should also be considered for specific applications.

5. How do I install a duckbill check valve?

Installation of duckbill check valves typically involves ensuring proper orientation, securing the valve in place, and connecting it to the system using appropriate fittings or connections. Follow the manufacturer’s guidelines and recommendations for installation.

6. Can duckbill check valves be used for high-pressure applications?

Yes, duckbill check valves can be designed and manufactured for high-pressure applications, but it’s crucial to select the appropriate materials and design specifications to meet the pressure requirements.

7. Do duckbill check valves require regular maintenance?

Duckbill check valves are known for their low maintenance requirements. However, periodic inspection to ensure proper functioning and cleaning to remove any debris buildup may be necessary, depending on the application.

8. Can I use duckbill check valves with corrosive fluids or gases?

Duckbill check valves can be made from materials that are resistant to corrosion. Ensure that the valve material is compatible with the specific fluid or gas in your application to prevent chemical damage.

9. Are there different sizes and shapes of duckbill check valves available?

Yes, duckbill check valves come in various sizes and shapes to accommodate different flow rates and system requirements. Customization options are also available to suit specific applications.

10. What is the typical lifespan of a duckbill check valve?

The lifespan of a duckbill check valve depends on factors such as the application, operating conditions, and maintenance practices. With proper care, these valves can have a long service life.

Remember that it’s essential to consult with valve manufacturers or experts to select the right duckbill check valve for your specific application and to address any additional questions or concerns you may have.

Reference : http://www.minivalve.com/newsite/index.php/en/by-type/duckbill-valves/how-they-work