what is gear train ?

A gear train is a mechanism that consists of two or more gears working together to transmit rotational motion and torque from one shaft to another. It is used to change the speed, direction, or amount of torque in a mechanical system.

Gears are toothed wheels that interlock with each other, and when they rotate, they transfer rotational motion. The gear that provides the initial input or receives the final output is called the driver gear, while the gear that is driven by the driver gear is called the driven gear.

The gear ratio of a gear train determines the relationship between the rotational speeds and torques of the driver and driven gears. The gear ratio is determined by the number of teeth on each gear. When a larger gear drives a smaller gear, the rotational speed decreases, but the torque increases. Conversely, when a smaller gear drives a larger gear, the rotational speed increases, but the torque decreases.

Gear trains are widely used in various mechanical devices and systems. They can be found in automobiles, bicycles, clocks, watches, and many other machines. They provide a way to transmit and control power efficiently and effectively in a wide range of applications.

Must Read : Planetry Gearbox

types of gear train

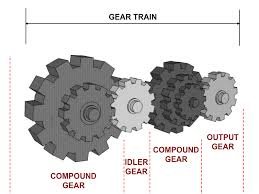

The different types of gear trains, depending upon the arrangement of wheels: 1. Simple gear train, 2. Compound gear train, 3. Reverted gear train, and 4. Epicyclic gear train.

Certainly! Here’s an expanded explanation of the different types of gear trains based on the arrangement of wheels:

- Simple Gear Train:

A simple gear train is a straightforward arrangement of two or more gears connected in series. Each gear is mounted on its own shaft, and the teeth of adjacent gears mesh with each other. The first gear in the train, known as the driver gear, transfers rotational motion to the second gear, called the driven gear. If there are additional gears in the train, the process continues. Finally, the last gear in the train delivers the output motion. In a simple gear train, all the gears rotate on their own shafts and have a fixed center distance between them. The gear ratio, which determines the relationship between the rotational speeds of the driver and driven gears, is determined by the number of teeth on each gear. The speed and torque in a simple gear train are inversely proportional, meaning that as the speed increases, the torque decreases, and vice versa. - Compound Gear Train:

A compound gear train is a combination of two or more simple gear trains that are interconnected. In this arrangement, the output shaft of one simple gear train becomes the input shaft of another simple gear train. By combining multiple simple gear trains, a compound gear train allows for greater flexibility in achieving specific speed and torque ratios. Compound gear trains are commonly used when a large gear reduction or increase is required. By strategically selecting the sizes of the gears in each simple gear train, different gear ratios can be obtained, providing the desired output speed and torque. - Reverted Gear Train:

In a reverted gear train, the arrangement of gears is such that the first and last gears are on the same shaft. The input and output shafts of a reverted gear train are parallel but rotate in opposite directions. The purpose of a reverted gear train is to change the direction of rotation while maintaining the same speed ratio. It is often used when it is necessary to reverse the direction of motion in a system, such as in some industrial machines. The advantage of a reverted gear train is that it allows for a compact design, as the input and output shafts are aligned. - Epicyclic Gear Train:

An epicyclic gear train, also known as a planetary gear train, is a complex arrangement that consists of three main components: a sun gear, planet gears, and a ring gear. The sun gear is located at the center and is surrounded by the planet gears, which are mounted on a common carrier. The planet gears mesh with both the sun gear and the ring gear, which is the outermost gear. The arrangement of gears in an epicyclic gear train allows for multiple axes of rotation and different speed ratios, depending on how the gears are held or locked. By changing the configuration of the gears, it is possible to achieve various gear ratios and torque outputs. Epicyclic gear trains offer versatility in achieving different speed and torque ratios, and they are commonly used in applications such as automatic transmissions, robotics, and power transmission systems where compactness and versatility are required.

Each type of gear train has its own advantages and applications. The choice of gear train depends on the specific requirements of the system, such as the desired speed ratio, torque requirements, space constraints, and the need for directional changes or compactness. By selecting the appropriate gear train, engineers can effectively transmit and control power in various mechanical systems.

Gear Train Components

Gear train components refer to the various parts and elements involved in the construction and functioning of a gear train. Gear trains are mechanical systems composed of multiple gears meshing together to transmit and control rotational motion.

Here are some common gear train components:

- Gears: Gears are the primary components of a gear train and consist of toothed wheels. They come in various shapes, sizes, and configurations, such as spur gears, helical gears, bevel gears, worm gears, etc. Gears transmit motion and torque from one shaft to another.

- Shafts: Shafts are cylindrical rods that support and rotate the gears. They provide a stable axis of rotation for the gears and transfer the rotational motion from one gear to another. Shafts are typically made of steel or other sturdy materials.

- Bearings: Bearings are used to support the shafts and reduce friction between rotating parts. They allow smooth rotation of the gears and prevent excessive wear and heat generation. Common types of bearings used in gear trains include ball bearings and roller bearings.

- Axles: Axles are shafts that connect and support the gears in a gear train. They transmit the torque and rotational motion from the driving gear to the driven gear.

- Gearboxes: Gearboxes are enclosures or housings that contain the gear train components. They protect the gears and provide lubrication to ensure smooth operation. Gearboxes also allow for the adjustment of gear ratios to control speed and torque.

- Clutches: Clutches are used to engage or disengage gears in a gear train. They allow for the selective transmission of power between gears, enabling the gear train to be stopped or changed without affecting other components.

- Sprockets and Chains: In some gear train configurations, sprockets (toothed wheels) and chains are used instead of gears to transmit motion. They are commonly found in bicycle drivetrains and industrial machinery.

- Lubrication System: It require lubrication to reduce friction, dissipate heat, and prevent premature wear. Lubricants such as oil or grease are used to ensure smooth operation and extend the lifespan of the gear train components.

These are some of the essential gear train components, but the specific components used can vary depending on the design and application of the gear train.

Gear Train Applications

Gear trains have various applications across different industries and mechanical systems. Here are some common applications of gear trains:

- Automotive Industry: It is extensively used in automobiles for power transmission and torque conversion. They are found in the transmission system, differential, and various other components. Gear trains help in changing the speed and direction of rotation between the engine and wheels, enabling the vehicle to move efficiently.

- Industrial Machinery: It is crucial in industrial machinery for transmitting power and controlling the speed of different components. They are commonly used in machines such as conveyor systems, packaging equipment, printing presses, and manufacturing machinery.

- Robotics: It play a significant role in robotics by transmitting torque and controlling the movement of robotic joints. They provide precise motion control and help achieve the desired positioning accuracy in robotic arms and other robotic systems.

- Clocks and Watches: It has been used for centuries in timekeeping devices. They are integral components of mechanical clocks and watches, ensuring the accurate measurement of time by regulating the rotation of hour, minute, and second hands.

- Aerospace and Aviation: It is employed in aircraft and spacecraft for various purposes. They are used in landing gear systems, control mechanisms, auxiliary power units, and engine accessories to transmit power and control the movement of different components.

- Power Plants: These are utilized in power plants, such as wind turbines and hydroelectric generators, to increase the rotational speed of the generator rotor. They help convert the relatively low-speed rotation of the turbine into higher speeds required for efficient power generation.

- Heavy Machinery and Construction Equipment: These are commonly employed in heavy machinery, such as excavators, cranes, and bulldozers, for power transmission and controlling the movement of mechanical parts. They enable precise control over the equipment’s functions.

- Agricultural Equipment: It find applications in agricultural machinery, including tractors, harvesters, and irrigation systems. They are used to transmit power from the engine to various agricultural implements and control the speed and direction of their operation.

- Marine Industry: These are essential in marine propulsion systems, such as marine engines and outboard motors. They transmit power from the engine to the propeller, enabling the vessel to move through water efficiently.

These are just a few examples of the wide-ranging applications of gear trains. Their versatility, durability, and ability to transmit power make them fundamental components in many mechanical systems across industries.

advantages of gear train

Gear trains offer several advantages in mechanical systems. Here are some of the key advantages of using gear trains:

- Power Transmission: It is highly efficient at transmitting power from one component to another. They can handle high torque loads and effectively transfer rotational energy, allowing for the efficient transfer of power between different parts of a machine or system.

- Speed Reduction or Increase: It enable speed reduction or increase by utilizing different gear ratios. By combining gears of different sizes, the rotational speed can be either decreased or increased, depending on the application. This flexibility in speed control allows for optimal performance in various systems.

- Torque Multiplication: It can multiply torque, which is beneficial in applications where high torque is required. By using gears with different numbers of teeth, the gear train can increase the output torque compared to the input torque, providing mechanical advantage in lifting heavy loads or performing tasks that require significant force.

- Motion Control and Precision: It provide precise control over the motion of mechanical systems. By selecting the appropriate gear ratios, desired speeds and movements can be achieved accurately. This is crucial in applications where precise positioning, timing, or synchronization of components is necessary.

- Compact and Space-Efficient: It can transmit power and achieve speed reduction or increase in a relatively compact space. This is particularly advantageous in applications where space is limited, such as in automotive transmissions, compact machinery, or small-scale devices.

- Durability and Reliability: It is known for their durability and long service life. Well-designed gear systems, with proper lubrication and maintenance, can operate reliably for extended periods. They can withstand high loads and resist wear, making them suitable for heavy-duty applications.

- Versatility: These are versatile and can be configured in various arrangements to suit different applications. They can be combined in series or parallel, allowing for complex power transmission systems and customization to meet specific requirements.

- Cost-Effective: It is cost-effective compared to alternative methods of power transmission, such as hydraulic or electrical systems. Gears are relatively simple to manufacture, and their widespread use contributes to readily available and affordable gear components.

These advantages make gear trains a popular choice in a wide range of industries and mechanical systems, where reliable power transmission, precise motion control, and efficient operation are essential.

disadvantages of gear train

While gear trains offer several advantages, they also have some disadvantages that should be taken into consideration. Here are some of the disadvantages associated with gear trains:

- Mechanical Complexity: It can be mechanically complex, especially in systems with multiple gears and gear stages. The complexity increases with the number of gears, leading to more points of potential failure. This complexity can make gear train design, assembly, and maintenance more challenging and time-consuming.

- Noise and Vibration: It can produce noise and vibration during operation. The meshing of gear teeth can generate vibrations and impact noise, especially at high speeds. In some applications, such as precision equipment or noise-sensitive environments, additional measures may be required to mitigate noise and vibration issues.

- Lubrication and Maintenance: It require proper lubrication to operate smoothly and minimize wear. Lubrication is crucial to reduce friction and dissipate heat generated during operation. Regular maintenance, including lubricant replacement and gear inspection, is necessary to ensure optimal performance and prevent premature wear or failure.

- Efficiency Losses: Despite their efficiency in power transmission, gear trains inherently introduce some level of energy loss due to friction and mechanical inefficiencies. The efficiency of a gear train can vary based on factors such as gear quality, lubrication, and misalignment. These losses can impact overall system efficiency and may require additional measures, such as bearing selection and gear design optimization, to minimize energy losses.

- Size and Weight: In certain applications, the size and weight of gear trains can be a disadvantage. Gear trains can occupy a significant amount of space, especially when multiple gears are involved. This can limit their application in compact or weight-sensitive systems where space or weight constraints are critical factors.

- Cost: While gear trains are generally cost-effective, certain specialized gear types, high-precision gears, or customized gear configurations can be expensive to manufacture or procure. Additionally, complex gear train systems may require additional components such as bearings, shafts, and housings, which can contribute to overall system costs.

- Limited Ratios: It is limited to specific gear ratios determined by the number of teeth on the gears. While this can be advantageous for achieving specific speed or torque requirements, it can also limit the flexibility and adjustability of the system. Changing the gear ratio often requires replacing gears, which can be time-consuming and may not be feasible in certain applications.

Despite these disadvantages, gear trains continue to be widely used and preferred in many applications due to their proven reliability, mechanical advantages, and versatility. Proper design considerations, maintenance practices, and optimization techniques can help mitigate these disadvantages and maximize the benefits of gear train systems.

Gear Train Maintenance

Gear Train Maintenance

Gear trains are mechanical systems that transmit power and motion between rotating shafts. They are commonly found in various applications such as vehicles, industrial machinery, and watches. To ensure the smooth operation and longevity of gear trains, regular maintenance is essential. Here are some key aspects of gear train maintenance:

- Lubrication: Proper lubrication is crucial for reducing friction and wear between gear teeth. Use the recommended lubricant specified by the gear manufacturer. Clean the gears thoroughly before applying fresh lubricant. Monitor lubricant levels and replace or top up as needed.

- Inspection: Regularly inspect the gear train for signs of damage, such as worn or chipped teeth, misalignment, or excessive backlash. Look for any abnormal noise or vibrations during operation. If any issues are detected, address them promptly to prevent further damage.

- Cleaning: Keep the gear train clean and free from debris or contaminants. Use compressed air or a soft brush to remove dirt and particles that may interfere with the gear meshing. Avoid using solvents that can damage the gears or lubrication.

- Alignment: Ensure proper alignment of the gear train components. Misalignment can lead to increased wear and premature failure. Check the gear meshing and adjust as necessary. Use precision tools and follow manufacturer guidelines for alignment procedures.

- Tension and Tensioners: In some gear train systems, tensioners or tensioning devices are used to maintain the optimal tension in the system. Inspect and adjust tensioners regularly according to the manufacturer’s instructions. Improper tension can cause slippage or excessive wear.

- Replace Worn Parts: Over time, gear teeth may wear down or become damaged. Inspect the gears periodically and replace any worn or damaged parts. Use high-quality replacement parts recommended by the manufacturer to ensure proper fit and function.

- Maintenance Schedule: Create a maintenance schedule based on the gear train’s usage and the manufacturer’s recommendations. Regularly perform maintenance tasks such as lubrication, inspection, and cleaning to keep the gear train in optimal condition.

- Professional Assistance: For complex gear train systems or if you’re uncertain about maintenance procedures, consider seeking assistance from a professional technician or mechanic with experience in gear train maintenance.

By following these maintenance practices, you can extend the lifespan of your gear train, minimize downtime, and ensure smooth and efficient operation. Always refer to the specific guidelines provided by the gear manufacturer for the best maintenance practices tailored to your gear train system.

Reference : https://en.wikipedia.org/wiki/Gear_train