In this article we are going to learn about types of pliers : Definition, parts, applications and its uses.

What is a Plier ?

Pliers Meaning : Pliers are a hand operated tools Which is used to handle and grip small objects or to bend and cut the wire.

What is Pliers Used For ?

Pliers come in a variety of shapes and sizes, and they have a wide range of applications. Some are designed to be used for gripping something round, such as a pipe or rod, while others are designed to be used for a variety of tasks, including cutting wire.

Different Types of Pliers and Their Uses

The following are the various types of pliers and their applications:

A) According To The Standard Types of Pliers

1. Slip Joint Pliers

Slip joint pliers are type of pliers which fulcrum can be easily adjustable to alter the width of the jaw. Hence, Because of the movable fulcrum, the jaws’ size range can be easily increased.

These pliers have a flat and serrated tip. The jaws of the pliers are curved out just below the tip for gripping rounded surfaces such as pipes. Slip joint pliers are found in almost every toolbox.

Uses :- It is used to crimp metal, loop wire, and cut soft nails. Slip-joint pliers can also be used to loosen and tighten nuts and bolts.But not used for cutting the wire.

This is also known or called as Water pump pliers.

The bolt of the fulcrum has a variety of marks to slip into when the jaws are open, allowing you to lock to a specific width. They’re commonly used in plumbing applications and can perform a variety of tasks, similar to a wrench.

2. Hose Clamp Plier

A hose clamp plier are designed to tighten the connection by compressing the hose and spring clamp.

It comes in Variety of designs. The most common type has a peg-shaped tooth in each jaw that pinches the clamp. Some models can also be used on the hose directly.

This pliers are also known as Radiator hose pliers and Spring clamp pliers.

Uses :- For compressing the hose and spring clamp ,making the joint tight.

3. Round/long Nose Plier

This pliers are designed tapered in length and conical.And this has not cutting edge.

Uses :- Needle nose pliers are extremely versatile, and can be used for a variety of tasks including electrical work (radio and TV job ), jewelry making, wire bending and twisting, and fishing.

They are of the long shaper type, and thus are also known as long-nose pliers. Because of their long shape, needle nose pliers can be used in smaller areas that other types of pliers cannot reach.

It is also known as pointy-nose or snipe-nose pliers.

4. Crimping Plier

A crumpling plier tool are designed in such a way which includes Fulcrum at the end which is used As a nutcracker.

To cut the fire, first Fed the wire into the jaw jack and then to the connector.

This tool are known as Crimping tools.

Uses :-

- Copper and aluminum wire should be cut.

- Forged carbon steel construction for strength and durability.

- Design of a comfortable high-leverage handle.

- The ability to accept both insulated and uninsulated power wire terminals.

- A thin nose enables cutting in confined spaces.

5. Diagonal Plier

Diagonal pliers are designed in such a way whose jaw have angled edge that is used to cut the wire. They are extremely strong and can also be used to cut nails.

As a result, they are useful in carpentry and electrical work.

Doagonal pliers are known by many names like diagonal cutters, diagonal cutting pliers, side-cutting pliers, etc.

The main functions of this tool is to cut any types of wire.

The diagonal plier’s function is similar to that of a simple scissor. They do, however, perform the cutting action differently. They cut the wire by indenting it and then wedging it.

When diagonal pliers are seen from the front, they form a “X” shape. Tempered steel is used to make these pliers. They go through the inductive heating process first, followed by the quenching process.

6. Snap Ring Pliers

These pliers have small, round jaws that help close the snap ring. These rings are open-ended loops that fit into the grooves of a dowel or other round object. When closed, the ring can rotate freely but cannot slide sideways. They are commonly used for gear on mountain bikes and other similar vehicles.

This pliers are commonly known as Circlip pliers or c-clip pliers. Often times they are named as lock ring pliers. Frequently, Often times it is named as lock ring pliers.

Applications of snap ring pliers :-

- This pliers are used to insert As well as remove the snap ring.

- Hikers use snap ring pliers for a variety of purposes.

7. Tongue And Groove Pliers :

Tongue and groove pliers are an adjustable type of pliers with a toothed groove along the upper handle, that allows the lower jaw to be locked into a number of positions. Because of the angled jaws, this tool is great for turning nuts and bolts.

Design

The Tongue and groove pliers have a simple design. Tongue and groove pliers have jaws that are set 45 to 60 degrees from the handles.

The lower jaws of the Tongue and groove pliers can be moved to a variety of positions depending on the application. These pliers are designed so that they can be adjusted to a variety of sizes without increasing the distance between the two handles.

Applications

- For turning and holding nuts and bolts, tongue and groove pliers are used.

- They are commonly used for gripping irregularly shaped objects and, sometimes, for material crimping.

- The Tongue and groove pliers’ design allows us to use them in applications where space is limited or a very small area is present.

- Their handles are extremely long in order to provide more leverage. Tongue and groove pliers have handles that range in size from 9.5 to 12 inches.

Because of their larger handles, these pliers are easily identified.It is also known as channel lock.

B) According to Special Types of Plier

1. Battery Pliers

Battery pliers are designed to used mainly in the automotive industry for maintaining bolts on car batteries and jumper cables. These pliers are made up of small angled jaws. The lower jaw is slightly shorter, and both jaws are thicker to make them more durable.

Uses of battery pliers :-

- Battery pliers are used in the automobile industry to maintain the bolts on the battery.

- It used for both top-post and side-post battery terminals.

2. Bent Nose Pliers

Bent nose pliers are consists of a set of jaws that bent at some angle at the midpoint ( generally 45 or 90 degree ).

The function of bent nose pliers is similar to that of needle-nose pliers; the only difference is that they have a bent nose.

By looking at their curved beak, we can easily identify bent nose pliers.

Bent nose allow them to Hold any surfaces when multiple Pliers are required or In the fase when It is very dificult to Reach an angle with Normal needle nose pliers.

Applications :-It is useful in jewelry making, electrical work, and other industries that deal with shaping wire.

3. Bail Making Pliers

The bail making pliers‘ jaws are made up of two cylindrical rods. Here, One rod is slightly larger than the other.

By looking at the jaws of the bail making pliers, we can quickly identify them. The pliers with the jaws that resemble cylindrical rods are the bail making pliers.

Uses of bail making pliers are :-

- Bail making pliers are used to make delicate items such as jewelry and other valuables things.

- They’re also used in the production of clasps and ear wires ,And many other shaped loop components.

4. Nail Puller Pliers

These pliers are specifically designed for pulling nails, as the name implies. Nail puller pliers resemble tongs in appearance, but their jaws are tapered.

These tapered jaws assist them in extracting the nails from the wood. The forged steel dominates the head of these pliers.

Uses of this pliers are following :-

To remove the staples, use nail puller pliers.

This type of plier is used by carpenters and people interested in woodworking.

5. Brake Spring Pliers

This is type of pliers used by mechanics to to handle the spring Which are inside the drum brakes.

It has two jaws and the jaws are very unique in shape.

One jaw is rounded, while the other is curved in shape. One jaw is used to remove the spring, while the other is used to insert it.

Uses of brake spring pliers are :-

Brake spring pliers are mainly used in the automotive industry.

They can also be used in applications involving the removal and insertion of springs.

6. Canvas Pliers

This is a type of pliers which has rectangular stripes on the jaw which is used to hold the wires.

The canvas players are made of chrome-plated steel. Teeth that are completely mated ensure a firm, non-slip grip. The handle has a built-in spring return that opens the pliers when you release.

They are also known as canvas stretching pliers.

Anyone can easily identify this pliers by Looking the jaw of pliers .There is a rectangular Strips on their jaws which is used To hold the wires.

Uses of Canvas pliers are :-

- It can be used to remove the Insulation of electric wire.

- It is used to hold the wire Or small rectangular Shaper long wire Type objects.

7. Chain Nose Pliers

Featuring the stubby triangular Jaw, The chain nose pliers, are one of many tools used in wire shaping and jewelry making. The jaw’s design allows the wire to bend, fold, and shape itself.

When working with beads, the tip aids in closing and opening the bead tips and jump ring.

8. Flat or Combined Pliers

This is a multi-purpose device.

The jaws of these multi-purpose devices are divided into three distinct segments. The first parts from the tip are serrated gripping surfaces. A round serrated section behind it makes it easier to grip tubes and other thick round objects.

Finally, there is a cutting surface in the proximal part of the base. The latter, which lacks a round center segment in the jaw, is frequently mistaken for linesman’s pliers.

Uses of flat or combined pliers are :-

- Combination pliers used to cut, grip, twist, and bend.

- Their jaws have a rough surface that works well for removing wire insulation.

Note :- This pliers should not be used to cut a very hard metal because the edge will be ruined. Parallel slots on the inner side of its jaws are made for a firm grip on jobs.

9. Eyelet Pliers

Eyelet pliers are a type of plier that is primarily used in the clothing industry. Its primary function is to incorporate laces and drawstrings into the cloth.

These eyelets have a ring and an elongated hub that must be crimped down.

Most modern eyelet pliers have interchangeable dies that allow for both hole punching and crimping, though some only have crimping surfaces or an upper jaw wheel with various die tips.

Uses of Eyelet pliers are :-

- In the clothing industry, eyelet pliers can be used to punch holes.

- The eyelet pliers are used to make the button hole on both the shirts and the jackets.

10. Fencing Pliers

When viewed from above, this multi-tool looking resembles a hammer with two handles. Notches in the fulcrum allow you to cut wires of various gauges, and the side of the left jaw has a hammer surface for driving in staples.

The claw of the right jaw can be used to remove staples, and the jaws themselves have a gripping surface and a rounded grip hole.

11. Grommet Pliers

Grommet pliers perform the same function as eyelet pliers, but they look different.

A distinctive structure can be found in the grommet pliers’ jaws. You can get a good idea of what the Grommet pliers are by looking at the image below.

Uses of Grommet pliers :-

- Grommet pliers have a wider range of uses than eyelet pliers

- The grommet pliers, to be more precise, can be used for complex and heavy applications.

- They are also used in the construction of tents.

- Grommet pliers are frequently used to make holes in hard materials.

12. Hose Grip Pliers

These specialized type of pliers are designed to easily carry small hoses into and out of tight spaces. Their grabber jaws are shaped to protect hoses such as vacuum lines, heater hoses, and fuel lines.

Simply hold the hose and turn or turn. Hose grip pliers are also useful for hose clamps, spark plugs, and a variety of other small components.

They are popularly known as the grabber pliers.

They have grabber jaws. Hose refers to pipes or tubing. The best way to recognize them is to look at their grabber jaw, which has a very distinct shape.

Uses of the hose grip pliers :-

- Plumbers use hose grip pliers in a variety of plumbing applications.

- Hose grip pliers are also ideal for clamps, spark plugs, and other small components.

13. Linesman Pliers

Lineman’s pliers are mostly used by linemen, that’s why they have such a name. Lineman’s pliers are primarily used for twisting, bending, and cutting wire.

Do you know how to recognize the lineman’s pliers?

Lineman’s pliers are distinguished by the flat gripping surface on their snub nose. So, if you come across a plier with a gripping surface on the snub nose, it’s the lineman’s pliers.

The Lineman’s pliers also have a beveled cutting edge, which is an important feature.

Lineman’s pliers are used in heavy-duty applications and are machined from forged steel. The rivet is used to control the accuracy of this plier type. Even when used in applications requiring greater force, the rivet prevents the pliers from breaking or being damaged.

Lineman’s pliers have two grips. These two grips allow you to easily handle them. These grips have an insulation layer on them. When working with electric wires, this insulation protects the users from electric shocks.

Some models of these pliers are designed to withstand higher voltages of up to 1000V.

Uses of linesman pliers :-

- Lineman’s pliers are most commonly found in electrical applications. They are employed in the bending, cutting, and straightening of wire.

- They are also used to strip wire from time to time. However, for the same applications, they are less efficient than a wire stripper.

- They are frequently used to pull the fish tape a few times.

- A few lineman’s pliers include a crimping tool, which is then used to compress the crimped connections.

- The square nose of the lineman’s pliers produces perfect right-angle bends.

- They can also be used to cut drywall and steel screws.

- The lineman’s pliers’ tapered nose can be used to ream the rough edge.

14. Locking Pliers

These pliers are designed to lock the jaws in place, making them useful for snatching screws and bolts.

An over-center toggle action is used in the locking pliers to lock into a specific position. The locking pliers have various uses in the manufacturing and design industries.

They are a very specific type of pliers that are sometimes referred to as Vise-Grips. William Petersen invented the first locking plier in the United States in 1924. Thomas Coughtrie invented Mole wrenches after the second type of locking pliers.

The mechanism involved in the locking pliers

The locking pliers are made up of two jaws. The bolt for adjusting the space between the jaws is housed in one of the handles. The lever for unlocking the pliers is located on the opposite side of the handle. The locking pliers are sold under the brand names Vise Grips and Mole.

In everyday life, mechanics in the United States refer to locking pliers as Vise-Grips, while mechanics in the United Kingdom refer to locking pliers as Mole Grips.

The bolt is used to tighten or loosen the jaws. They are kept in such a way that they are smaller than the object to be gripped.

The jaws are now fixed on the gripped object.

Advantages of locking pliers are

- They can be used to generate more force because their lever action is far stronger than that of other types of pliers.

- With the locking pliers, you can easily apply a controlled force.

- The locking pairs can remain close without the need for human intervention.

- Locking Pliers are useful for a variety of tasks.

Uses of locking pliers are :-

- In the case of holding metal parts, a very common application of locking pliers is found.

- You may have come across applications where we needed to hold pipe without squeezing it.Locking pliers are essential in such applications.

- Locking pliers are also used to secure the rounded nut or bolt.

15. Piston Rings Pliers

Piston ring pliers are used to remove engine piston rings. There are two kinds of piston ring pliers. Cast iron is used to make these pliers. The curved tip of the piston ring pliers distinguishes it and allows us to easily identify it.

Uses of piston rings pliers are :-

- Piston ring pliers are used in the automotive and engine industries, as well as in other fields where engines are present.

- They are also sometimes used to provide a seal between the piston and the cylinder wall.

16. Running Pliers

This pliers make a clean break along the run lines in the glass. The wide jaws are adjusted to match the thickness of your glass and have a centerline to ensure precise alignment when moving with the score. They are used to make stained glass crafts.

17. Sheet Metal Pliers

Sheet metal pliers, as the name suggests, are used in industries that work with sheet metal. The jaws of these pliers are wide and rectangular.

These types of pliers are identified by their rectangular unique jaws. The jaws of sheet metal plier scan be used to bend sheet metal and for the formation of seams.

18. Spark Plug Pliers

These pliers have insulated tongs or a cylindrical holder attached to their narrow jaws.

As the name suggests, the tips hold the spark plugs by boot or plug wires, assisting in automotive repair.

The jaws of welding pliers are similar to those of combination pliers, with the needle having the same tip as the jaw of the nose plier.

Uses :- They are capable of a wide range of tasks, including splatter removal, wire gripping, cutting, and hammer handling. As the name implies, these pliers are commonly used in welding-related trades.

20. Split Ring Pliers

The split ring pliers have a bent tip on its lower jaw. This nozzle acts as a wedge, splitting individual coiled rings. They are used in the production of fishing tackle and keyrings.

This pliers are also known as fishing pliers.

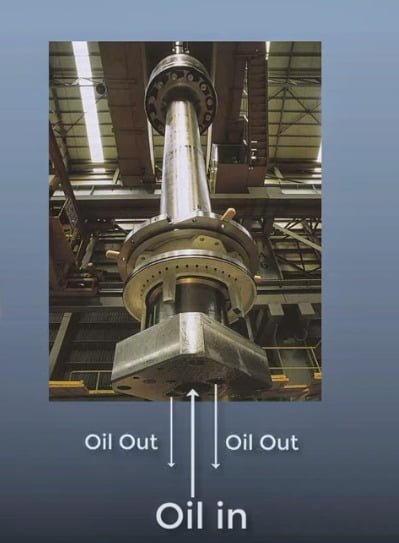

21. Oil Filter Pliers

Oil filter pliers are a special type of plier that can only be used in a specific industry. Their jaws are toothed and formed into a C shape.

To get a better idea of the oil filter jaws, look at the image below.

Uses of oil filter pliers :-

- In the automobile industry, oil filter pliers are used.

- Second, they’re employed in the removal of oil filter casings.

22. Soft Jaw Pliers

Many different types of pliers are included in the soft jaw pliers. The difference is that these pliers have padded jaws to prevent scratches on chrome and other soft metals or exposed surfaces.

Uses :- They are primarily used for plumbing and scuba diving equipment.

23. Gas Pliers

These pliers are used to open nuts on gas and oil pipes, among other things. Like slip joint pliers, it has an opening that can be enlarged or closed as needed.

Precautions of using Gas pliers

This Pliers should never be used in place of a hammer, spanner, or wrench.

Different pliers should be used for different jobs.

24. Push Pin Pliers

Push Pin Pliers are used to remove plastic push pins. It protects the anchors and pins from damage. The jaws of the push pin pliers are wedge-shaped to help remove the anchors more effectively.

The wedge-shaped jaws of such pliers make them easily identifiable. Because of the available springs, they provide us with more comfort.

Uses of push pin pliers are :

- Push pin pliers are used in automotive work.

- They are also used in processes where pin-style anchors are commonly used.

25. Wire Twisting Pliers

The jaws of wire twisting pliers are very short. It has two jaws and both of the jaws have a cutting edge.

A knob and a special cylindrical locking mechanism are located between the two handles of the wire twisting pliers.

By paying attention to the above description, we can easily identify the wire twisting pliers.

With the help of this locking mechanism, the entire wire spins and we get the required twisting. With the help of the wire twisting pliers, we can twist many wires at the same time. We can twist multiple wires at the same time using wire twisting pliers.

Uses of wire twisting pliers :-

- Wire twisting pliers are used by electricians as well as in the electronics industry.

- Sometimes, Such pliers are also used by jewelers

With this article we have tried to incorporate all the types of pliers that are being used in the various Industries along with their images for proper understanding and visualization. the Pliers images will help you to remember and understand the various types of pliers accordingly. If you liked this article please share it with your friends.

Check Out Other Important Topics

IC Engine

Electrical

Important PDFs

Boilers

Synergy Maritime Exam

Naval Arch

Interview Questions

Difference Between

Types of Pumps

Types of Valves

MEO Class 4

Auxiliary Machines

Home