In this article we will Discuss about flat, recover, Compare and Different Types of Files Tool & Their Uses along with the right process of filing and what are the application of filing tools.

Most widely used hand tool to be found in an engineering workshop is the file. A file is a hardened piece of high grade steel with slanting rows of teeth. It is used to cut, smooth, or fit metal parts. It cuts all metals except hardened steel.

Parts of a file

- Handle

- Tang

- Heel

- Face

- Edge

- Point

A file consists of the following part as shown in fig. The tang is the pointed part which fitted into the handle. The safe edge or side of a file is that which has no teeth.

Files are classified and named according to the three principal factor-sizes, type or cut of teeth, and sectional form.

1. Types of Files Tool According to the Size

Size :- The size of a file is its length. This is the distance from the point to the heel, without tang. Files for fine work are usually from 100 to 200 mm and those for heavier work from 200 to 450 mm in length.

2. Types of Files Tool According to Cut of Teeth

Cut of teeth :- Cuts of files are divided into two groups as shown in fig. These groups are : (1) single-cut (2) double-cut.

1. Single-cut files :-

On single -cut files the teeth are cut parallel to other across the file at an angle of about 60° to the center line of the file. Such files are frequently termed as “flats” and are chiefly used on very hard metal.

2. Double-cut files :-

Double cut– files have two sets of teeth, the over-cut teeth being cut at about 60° and the up-cut at 75 to 80° to the center line.

Single-cut and double-cut files are further divided according to the coarseness or spacing between the rows of the teeth. In descending order of roughness they are listed as :

- Rough (R )

- Bastard (B )

- Second cut (SC )

- Smooth (S )

- Dead smooth (DS )

- Super smooth (Ss )

Table 14.2 will give a fair idea of the number of teeth or cut in each of the above grades over a length of 10 mm. It will be seen from the table that the coarseness of a file changes with its length. The larger the file, the coarser it is. Thus, a rough cut, on a small file may be as fine as a second-cut on a larger file.

Rough cuts are used for soft metals. They are often used for trimming the rough edges of castings of softer metals. Bastard is the standard cut used for general shaping work. Second cut is an excellent file for harder metals and gives a good finish for may pieces of fitting work. Other cuts are used to give a high degree of accuracy with a very high finish.

3. Curved Cut File :-

This is also known as the Vixen file. The curved-cut file is used for filing wide surfaces of soft metals such as aluminum, zinc, copper, and brass. It has circular teeth, as shown in fig.

4. Spiral Cut File :-

Spiral cut files have teeth which are cut in round or semi-round files. The shapes of their teeth are like that of threads.

5. Rasp Cut File :-

Rasp cut files have special thick. These teeth have a triangle shape and bulging state.

This tool is used for jobs of woods, plastic, fiber, hard rubber, and job of horns and hoof of animals.

3. Types of Files Tool According to Grade

According to the basis of the number of the teeth, different types of files tool are following :

1. Rough File :-

Rough files have teeth of big sizes and number of teeth is very less. This is used to cut soft materials because it’s cutting is rough. It can not used for hard metal because of the rough cutting.

2. Bastard File :-

The sizes of the teeth of thus files are comparatively smaller than those of rough file .It is used initially for shedding metal (through filing) in large quantity.

3. Second cut Files Tool:-

This is a medium-grade file. This file is mostly used in the filler trade to bring the job in the correct size. When compared to the bastard file, filing with this file makes the surface plain.

4. Smooth Files Tool :-

This file is used for making the surface quite plain, in addition to making a job of accurate size through filing.

4. Types of Files Tool on the Basis of Shapes

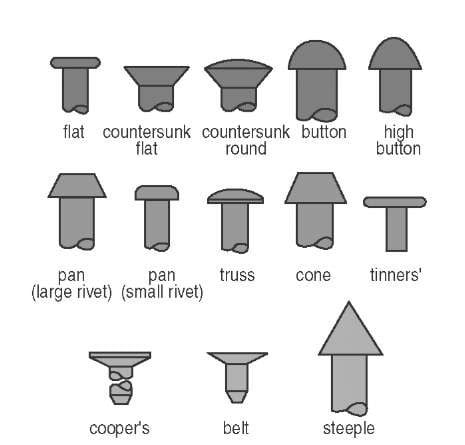

Shapes :- The shape of a file is its general outline and cross-section. Files are made in hundred of shapes. Fig show the most commonly used shapes. They are :

1. Flat File :

Flat file is types of files tool which is tapered in width and thickness, and one of the most commonly used files for general work. They are always double-clutching on the faces and single-cut on the edges.

2. Hand File :

This is parallel in its width, and tapered in thickness. A hand file is used for finishing flat surfaces. It has one edge (i.e it is uncut) and therefore, is useful where the flat file cannot be used. They are always double-cut.

3. Square File :

This is square in cross-section, double-cut, and tapered towards the point. This is used for filling square corners, enlarging square or rectangular openings as splines and keyways.

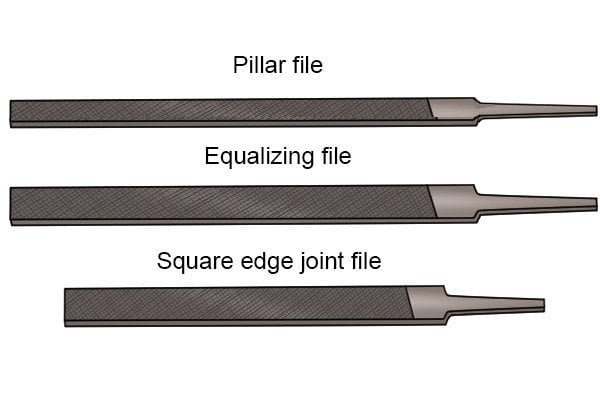

4. Pillar File :

Pillar files are double-cut narrow and of rectangular section. It has one safe edge, and is used for narrow work, such as keyways, slots and grooves.

5. Round File :

They are round in cross-section and usually tapered, when they are termed rat-tailed. When parallel they are described as parallel round. Round files are used for filling curved surfaces and enlarging round holes and forming fillets. They may be single-cut or double cut.

6. Triangular Files Tool :

Three square or triangular file is tapered, double-cut, and the shape is that of an equilateral triangle. They are used fir rectangular cuts and filing corners less than 90°.

7. Half-round File :

This is tapered double-cut and its cross section is not a half circle but only about one-third of a circle. This file is used for round cuts and filling curved surfaces.

8. Knife Edge Files Tool :

This is shaped like a knife, tapered in width and thickness and double-cut. They are used filing narrow slots, notches, and grooves.

There are a number of other types of files tool in less common use. They are all used for special purposes and not in general use. They are wording file, needle file, riffer, etc. A wording file is a thin flat file having fine cut teeth, about 100 mm long. This is widely employed for all kinds of fine work.

A needle file is made in sizes from 100 to 200 mm, of various shapes and cuts. They are extremely delicate and are used for fine work. Rifflers are curved upwards at the ends into an arc. They are used to reach the bottom of a sinking and for filing the insides of a castings.

Specification. When ordering a file following informations should be given :

1. Length, say, 100mm.

2. Shape, say, flat

3. Single or double cut

4. Roughness, say, bastard

Filing

Filing is the most important operation that a metal worker has to learn. Filing is usually an after-treatment and usually done after chipping. It serves to remove the burr from the cuts and clean the face of the cuts, and to finish the finals shape of a workpiece. In general no more than 0.6 mm tooling allowance should be left for filing. Filing allows work to be made accurate to 0.05 mm, in some cases 0.02 mm and even 0.01 mm.

Methods of filing

Generally speaking there are three main methods of using a and flat file:

Cross filing :- In cross filing the file strokes run alternately from the right to the left as shown in the figure. This is the commonest form of filing and the one used for general shaping. In this method ,the possibility of rounding is minimized, and the score marks made in the work by the file teeth and crisis- crossed so that maximum amount of metal is removed. The aim in cross filing is always to move the whole of the file surface of the across the whole of the work surface in one stroke.

Straight filing :- In straight filing the file is pressed forward approximately at right angles to the length of the work. On the back stroke, the files should be lifted clear of the work in order not to blunt the teeth straight filing is especially useful on long and narrow piece of work which is less than that of the file.

Draw filing :- In draw filing the handle the file is not held. Instead, both bands are placed to close together on the blade as shown in the figure. The file is placed at right angle across the work fine on the hands and especially the thumb, grip the file and move it up and down the length of the metal. It is not move much material, but a smoother cutting action is achieved them with cross or straight filing.

How to do Proper Filing

The following points must be considered in order to obtain the proper surface through filing:

- Choose the appropriate types of files tool for the job work.

- A handle should be attached to the tang of the file. In small files, a small handle should be used, and in larger files, a larger handle should be used. Otherwise, proper and power would be squandered unnecessarily.

- Hold the file handle with your right hand while keeping the file end balanced with your left.

- When filing, keep the left leg ahead and the right leg slightly behind, as shown in fig.

- Pressure should be applied to the file while it is being moved forward, not while it is being driven back.

- Only your hands, not your entire body, should move with the file. Keep the rest of your body as still as possible.

- The file should be moved at a rate of 30 to 35 strokes per minute.

Precautions

- Choose the appropriate file for the job.

- Do not use a file that does not have a handle. The entire handle should be fixed on the file based on the size.

- A new file should be used on soft metal first, and then on solid metal

- If a substantial material is to be cut, chipping should be done first, followed by filing.

- For filing the sheet metal jobs, The job work should be fixed in the vice by using the wood on both its sides. It should also be ensured that the sheet should not be higher than vice.

- We should cut a sheet in length while filing it.

- To prevent the job from being pinned, we should use chalk. A brush should be used to remove any metal particles from the file.

- Keep it separate from the rest of your tools. They should not be piled on top of each other.

- Heat should not be applied to the file.

- The file should not be oiled or greased.

Applications of Files Tool

- A file is used to give the final finishing touches to a metal or wood job.

- After chipping, a metal job usually becomes rough, and a file is used to smooth it out.

- In the case of a machine, if the part is larger than the required size, a file is used to reduce its size.

- In addition, this is used where the other cutting tools cannot be used.

- Files can also be used to sharpen the edge of other cutting tools.

With this article we have covered all the topics related to Files like What are Files tool, Types of Files tool and how to do filing, what are the Applications of Filing Tools, What are the methods of filing.

Check Out Other Important Topics