What is Vapour absorption refrigeration system ?

Vapour Absorption refrigeration system is a system which is similar to compression cycle and it uses a heat source (e.g., solar energy, a fossil-fueled flame, waste heat from factories, or district heating systems) to provide the energy needed to drive the cooling process.

The system employs two coolants, the first of which performs evaporative cooling before being absorbed by the second; heat is required to return the two coolants to their initial states.

Vapour absorption refrigeration systems (VARS ) include all processes of a vapor compression refrigeration system, such as compression, condensation, expansion, and evaporation—the refrigerant used in Vapour absorption systems is ammonia, water, or lithium bromide.

The refrigerant condenses in the condenser and evaporates during evaporation. The refrigerants cool the evaporator and release heat to the atmosphere via the condenser.

Vapour Absorption refrigeration system vs vapour compression system

The main between between the two systems is the method of suction and compression of refrigerant in the refrigeration cycle. In a Vapour compression system, the compressor draws refrigerant from the evaporator and compresses it under high pressure.

The compressor also allows refrigerant to flow throughout the refrigeration cycle. A suction and compression process is carried out by two different devices known as absorbers and generators in the vapor absorption cycle.

Thus, in the vapor absorption cycle, the absorber and generator take the place of the compressor. The absorber allows the refrigerant to flow by absorbing from the absorber to the generator. Another significant difference between vapor compression and vapor absorption cycles is the method by which energy is supplied to the system.

The energy input to a vapor compression system is expressed as a mechanical function of an electric motor driven by an electric motor. Heat is the form of energy input in a vapor absorption system. This could be due to the heat process or steam passing through hot water.

Other sources of heat, such as natural gas, kerosene, heaters, and so on, can also produce heat, though these are only used in small systems.

Why Vapour absorption refrigeration system (VARS) was needed:

Vapour absorption refrigeration system (VARS) was mainly required because vapour compression refrigeration system (VCRS) consumed a large amount of power and was not practical or affordable in areas where power was scarce or expensive.

The vapor absorption refrigeration system uses heat energy to cool, whereas the vapor compression refrigeration system uses work energy to cool, which is much more expensive to produce.

Vapour absorption refrigeration systems are best suited for locations where heat energy is readily available and inexpensive. This method is ideal for steam power plants. This refrigeration system can be easily powered by steam power plants using waste heat generated in the power plant.

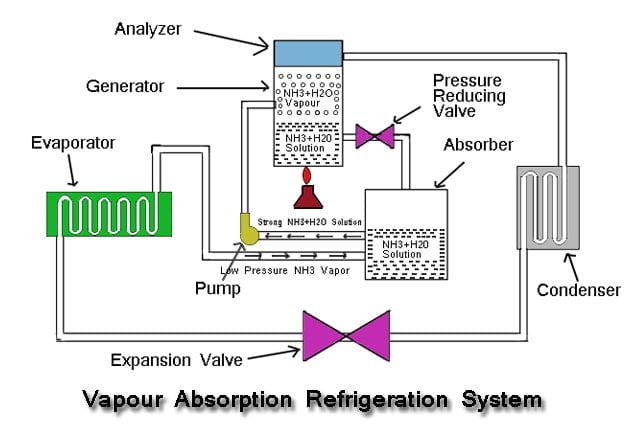

Components in Vapour Absorption Refrigeration System:

Vapour Absorption Refrigeration System components are following :-

- Evaporator

- Absorbers

- Pump

- Generator

- Analyzer

- Pressure reducing valve

- Condenser

- Expansion valve

1. Evaporator

We have an evaporator where the refrigeration effect or the cooling effect takes place.

The primary function of evaporators is to provide cooling to the area with which they come into contact. The cooled liquid will enter this evaporator, receive heat from the evaporator, and be converted into vapour. This Vapour will be under low pressure. The ammonia vapour is expelled under low pressure from this evaporator and is directed toward the absorber.

Location :- It lies between the Expansion valve and Absorber.

Note :- Refrigerant enters in the evaporator in the liquids conditions having low temperatures and low pressure. When refrigerant come out then it in vapour conditions having low pressure.

2. Absorber

Absorber contains the solution of ammonia and water.

Absorbers are devices that are used to absorb refrigerants. A weak solution of water and ammonia will be present in the absorber. When the ammonia vapour from the evaporator reaches the absorber, it is absorbed by the water in the absorber. As the ammonia is absorbed by the water, a strong ammonia solution and water will form.

When water absorbs ammonia, it is liberated from the heat and its absorptive capacity is reduced. As a result, cold water is supplied to the absorber, increasing its absorptive capacity and ensuring that ammonia vapor is continuously absent.

Location :- It lies between the evaporator and the pump.

Note :- Refrigerant enters in the absorber in the vapour conditions having low pressure.

3. Pump

The pump is placed beside the absorber, which is used to pump, is ammonia water solution from the absorber to the generator.

Location :- It is between the absorber and the generator.

4. Generator

Inside this system, ammonia and water solutions are used. Water is used as an absorbent and ammonia as a refrigerant.

Because water has a strong affinity for ammonia, they combine to form a solution. The absorber contains both water and ammonia solutions.

Auxiliary heat is supplied to the generator from the outside. This auxiliary can provide heat, steam, hot water, or any other type of heater. Heat is applied to convert the ammonia and water solution into vapor.

5. Analyzer

The analyzers are mounted on top of the generator. Ammonia will convert to vapour before water, but some water particles will also convert to vapour. This analyzer is used to separate water particles from ammonia vapor.

If water particles pass through the generator, the overall efficiency of the system suffers. Water particles moving in large numbers can also harm the system.

As a result, the analyzer condenses the water particles, but the ammonia vapour passes through the analyzer and continues into the system. Some ammonia will condense in the vapor analyzer as well, but the majority of the ammonia will pass through the vapor analyzer.

6. Pressure reducing valve

After the ammonia Vapour has passed through the analyzers, the weak solution in the generators will pass through the pressure reducing valve and return to the absorber.

7. Condenser

Condensers are used to convert ammonia vapour into liquid. These condensers can be either water-cooled or air-cooled.

A condenser, converts the incoming Vapor refrigerant into liquid by changing its face.

Location :- It is fitted between generator and Expansion valve.

Note :- Conditions of refrigerant before the condenser is in vapour having high pressure. After the condenser , refrigerant become liquid.

8. Expansion valve

An expansion valve which expands the liquid refrigerant ammonia decreases, the pressure and turns it into a culture, low temperature, low pressure liquid, which will go to the evaporator. So, these major components together

Its primary functions are to convert the liquid to cold liquid and to transport it to the evaporator.

The ammonia will enter the expansion valve from the liquid condenser, and the temperature and pressure of this liquid ammonia will decrease, and this ammonia will become the temperature of the liquid-cooled liquid ammonia, which will be much lower.

Location :- It is between the condenser and evaporator.

Note :- Refrigerant enters in the expansion valve in liquid having high pressure and exit in the condition of liquid having low temperatures and low pressure.

Components

The major parts and components and basic working procedure of vapour, absorption refrigeration system. First of all clear. We have an evaporator where the refrigeration effect or the cooling effect takes place.

There is an absorber which contains the solution of ammonia and water.

The pump is placed beside the absorber, which is used to pump, is ammonia water solution from the absorber to the generator.

There is a generator with a analyzer the top of it. A pressure reducing valve, a condenser, which converts the incoming Vapor refrigerant into liquid by changing its face. And finally, over here.

There is an expansion valve which expands the liquid refrigerant ammonia decreases, the pressure and turns it into a culture, low temperature, low pressure liquid, which will go to the evaporator. So, these major components together, construct, the vapour absorption refrigeration system. All these components are connected together by a pipe.

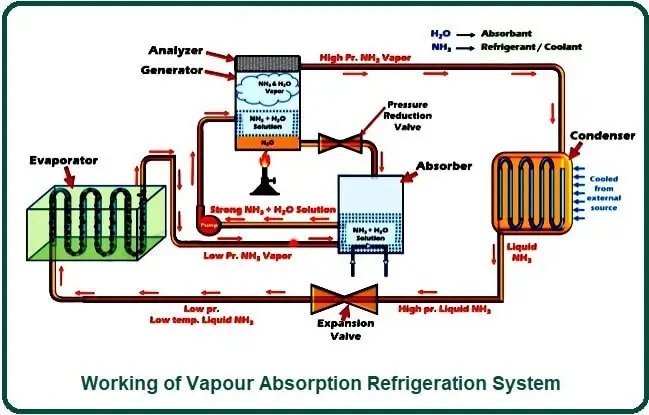

Working of Vapour absorption refrigeration system

When low pressure very cold chilled Low temperatures liquid Ammonia will enter the evaporator coils it will absorb all the heat present in the surface of the evaporator coils. By absorbing all the heat from the surrounding region of the evaporator coils . This cold chilled liquid ammonia will turn into low pressure. Ammonia vapour inside these coils and the surrounding surface of the evaporator will become cold by losing the heat to this liquid, thus the cooling effect or refrigeration effect occurred in the evaporator.

# After that, this low-pressure Ammonia Vapor will leave the evaporator and enter the absorber through the connecting pipe. The absorber already has a weak solution of ammonia and water inside it. And when this low-pressure ammonia vapour enters the absorber, the water present in the weak solution of this absorber will start absorbing this ammonia vapor and the weak solution will gradually convert into a strong ammonia water solution. The more ammonia Vapor coming from the evaporator is absorbed by water from this week solution. The stronger, this solution will become but when water absorbs, ammonia Vapor it also liberates heat, that is when water it will absorb the incoming ammonia Vapor it will produce heat which will increase the temperature of the solution. And when the solution becomes hot gradually the capacity of water to absorb ammonia decreases.

So to keep the temperature of the solution to an optimal level, a supply of cool water is provided through the pipe (see figure )so that this external supply of cool water through. This pipe carries away, heat from the solution and thus water regains, the capacity to continuously absorb incoming, ammonia Vapor.

# Beside this absorber, there is a pump. Now when power is provided, then this pump starts working. Then using this pump, this solution of ammonia, and water will be pumped from this absorber to the generator. So, the function of this pump is to transfer the solution from the absorber to the generator. We provide auxiliary heat or external heat to this generator either by using steam or hot water or any leader gas burner etc.

When the solutions of ammonia and water reaches the generator and heat is applied to this solution from the external source. Both ammonia and water from this ammonia water solution turns into vapour inside this generator . Actually ammonia turns into vapour faster than water and water takes comparatively more time to completely turn into vapour but eventually both ammonia and water will turn into vapour when heat is provided .

# An analyzer on the top of the generator when this vapour of ammonia and water pass through this analyzer, only amonia is allowed to pass through the analyzer continuosly condenses the water vapour and sends water back to the generator. This is because of water vapour enters the systems it can decrease the efficiency of the refrigeration system or if larger quantity of water vapour enters the systems then the system could be damaged. This, analyzer separates water particles from ammonia vapour and only keta ammonia through the next components through the pipe for further process.

# The analyzer sends water particles back to the generator then from this generator , the residue weak solution of water and ammonia accumulated here will be passed back to the absorber again passing through this pressure reducing valve.

# So here the high pressure high temperature pure ammonia vapour coming out of the generator will now enter into condenser through connected pipe .Here, we have a condenser l, when high temperature high pressure ammonia vapour enters this cold condenser then the condenser absorbs the heat from ammonia vapour and completely converts it into liquid. This condenser can be either water cooled or air cooled or cooled by any substance from external source which will liberate the latent heat of this vapour coming into the condenser and thus, condensing keeps happening..

# we have an expansion valve after the condenser. Condensation liquid ammonia will leave the condenser and pass through this expansion valve. Now, this high pressure liquid ammonia coming from the condenser will be expanded inside this expansion valve. We know that when expansion occurs the pressure between the the molecules decrease considerably. Thus, the temperature falls so, this high pressure liquid ammonia will be expanded into low pressure low temperatures liquid ammonia thus, we get very cold chilled low temperatures liquid coming out of the expansion valve .

Then, thus liquid ammonia will again passed over to the evaporator through connected pipe way by absorbing all the heat from the surrounding region of the evaporator coils. This cold chilled ammonia will again turn into low pressure ammonia vapour inside these coila and the surrounding region of the evaporator will become cold by losing the heat to the liquid then thus low pressure ammonia vapour will leave the evaporator and enter the absorber through the connecting pipe and whole cycle will be repeated over and again thus refrigeration occur or cooling or vapour Absorption refrigeration system occur.

Single-Effect and Double-Effect Cycles:

The temperature of the heat source is critical in Vapour absorption refrigeration systems. The heat provided by the source can be used in a single phase or in multiple phases. As a result, the system is referred to as a single-phase or single-effect cycle of operation, and if heat is supplied in two phases, the system is referred to as a two-phase or dual-effect cycle of operations.

When the heat sources reach temperatures of up to 105 ° C, the heat is used in a single phase, and the cycle is a single effect cycle. When the heat source temperature exceeds 105 ° C, the heat is typically used in two stages, and the system becomes a double impact cycle.

1. Single Effect cycle

A single-effect cycle system for Vapour absorption refrigeration systems is a simple and practical absorption system that uses ammonia as an absorber and refrigerant, as described in previous articles.

2. Double effect cycle

The double-effect system is depicted schematically. As shown, refrigerant vapour is produced in two stages. Two heat exchangers are used for this purpose.

People also ask ( Frequently Asked Questions )

Why is refrigeration system ?

The term refrigeration refers to the process of cooling a space, substance, or system in order to lower and/or maintain its temperature below that of the surrounding environment. In other words, refrigeration is the process of artificially cooling something. Heat is extracted from a low-temperature reservoir and transferred to a high-temperature reservoir.

Refrigeration systems work through a series of thermodynamic processes that form a cycle that returns the working substance to its original state. A thermodynamic refrigeration cycle removes heat from a low-temperature object and rejects it at a higher temperature (refrigeration).

What is refrigeration cycle ?

Refrigeration cycle is a cycle of mechanical system in which transmission of heat flow from one place at a lower temperature (the source ) to another place at a higher temperature ( the sink or heat sink ) by continuously circulating, evaporating, and condensing a fixed supply of refrigerant in a closed system.

Refrigeration cycle is thermodynamic cycle to generate refrigerating effect with the use of evaporator, compressor, condenser & expansion valve.

What is the purpose of refrigeration system ?

The fundamental reason for having a refrigerator is to keep food cold. Cold temperatures help food stay fresh longer. The basic idea behind refrigeration is to slow down the activity of bacteria (which all food contains) so that it takes longer for the bacteria to spoil the food.

Types of refrigeration system

- Evaporative Cooling: Evaporative cooling units are also known as swamp coolers. They work by blowing warm outdoor air over wet pads. The water’s job is to absorb heat from the air. The water then evaporates, allowing cooler air into your home while keeping warm air out.

- Mechanical-Compression Refrigeration Systems: Mechanical compression is used in commercial and industrial refrigeration, as well as air conditioning. This type of cooling system is commonly installed by HVAC companies.

- Absorption: The process of absorption refrigeration is similar to that of mechanical compression in terms of heat transfer. Absorption systems, on the other hand, use refrigerants that attract and absorb other substances rather than a mechanical compressor.

- Thermoelectric systems do not require water or any type of refrigerant. They are powered by a thermocouple and an electric current. When current is applied to the thermocouple, one end becomes hot and the other becomes cool. The thermocouple’s cold side is placed in the area that needs to be cooled so that it can attract and remove heat from the air.

What are the four stage of refrigeration system?

The compressor, condenser, expansion valve, and throttle valve are part of the Vapor Compression Refrigeration Cycle.

What are the four major components of refrigeration cycle ?

- Compressor

- Condenser

- Expansion valve

- Evaporator

Law of refrigeration

According to the Second Law, in order for heat to flow from a cold body to a hot body, all refrigerators must be worked on. The limitations of heat transfer are described by the Second Law of Thermodynamics.

Check Out Other Important Topics

| IC Engine | Important PDFs | Boilers | Synergy Maritime Exam | Naval Arch | MEO Class 4 |

| Interview Questions | Difference Between | Types of Pumps | Auxiliary Machines | Types of Valves | Home |