In this article ,we will explain in details , what is pulley ? Types of pulley ? How does it works ? pulley meaning, parts, Applications, Advantages, Disadvantages. Uses with pictures and examples.

What is Pulley ?

The pulleys are a mechanical device which is used to transmit the power from one shaft to the other at a moderate distance away by means of a belt or strap running over them.

It is a simple machine which is used for transferring motion from shaft to belt or rope and vice versa.

A rope, cable, belt, or chain is the primary component of a pulley system. “Driver Pulleys” are pulleys that are fixed to a shaft or pulley that moves other pulleys. The pulleys that are moved by the driver pulley are referred to as “Follower Pulleys.” Pulleys are available in two sizes: small and large.

By using large and small pulleys, we can easily increase or decrease the speed of power transmission in terms of gears and shafts.

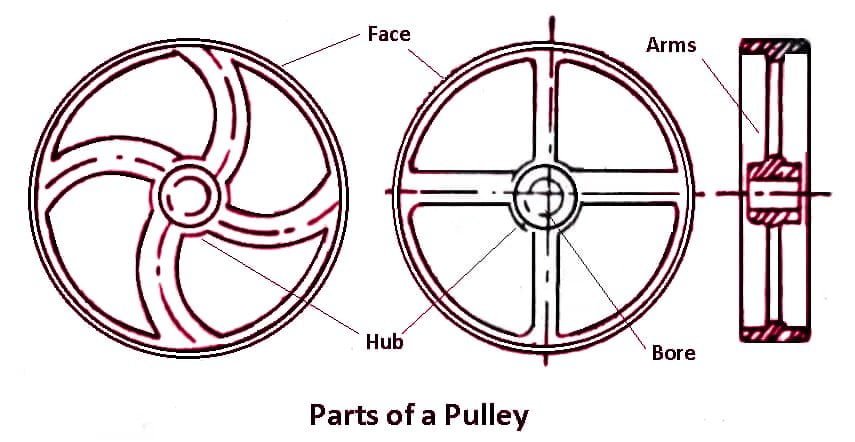

Parts of Pulleys

The different parts of pulleys are following :-

- Face

- Hub

- Arms

- Bore

Face

The Face refers to the part of the pulley that contains the pulley’s periphery. It extends somewhat from the center and descends from the sides. The protruding middle section is known as the Crown. The face is either plain or has a “V” groove built into it.

Hub

The hub is the central part of a pulley that has a shaft bore. There are three kinds of these:

a) Solid Hub: Only a single shaft of a specific size is used. It is used with various bores for shafts of various sizes.

b) Slotted Hub: It has a slot on one side that is tightened with a nut and bolt after the shaft is fitted. It’s also made in a single piece. It is suitable for use with shafts of various diameters.

c) Split Hub: A split hub is made of two parts. Two nuts and bolts are used to secure these two parts to the shafts. Their faces are composed of two parts. These are suitable for both large and small shafts of the same type.

Arms

Arms are the connecting parts of pulleys that join the pulley’s face and hub. Their number is determined by the diameter of the pulley and its application. It can be made with four, six, or eight pieces.

Bore

Bore refers to the hole in the hub. A key method is to drill a hole and lock the key shaft and pulley.

Applications of Pulleys on everyday life

1. Elevators :- Elevators operate on the basis of a powerful electronic pulley system. Elevators, in fact, use a system of pulleys and counterweights to provide both power and safety to the lift system.

2. Well :-To lift the bucket out of an old-fashioned “wishing well” style water well, a simple pulley system is used.

3. Exercise Equipment :- Pulleys are commonly used in weight-lifting exercise equipment to control the angle at which weights are lifted while keeping the weights themselves in a specific location. This makes weight lifting safer and more effective for the user than free weights, which may be dangerous if used incorrectly.

4. For construction :-Construction pulleys are some of the most basic and common pulleys, and they are useful for understanding how this simple machine works. These pulleys are made up of a wheel track that can be raised to great heights and is outfitted with chains or rope attached to hooks.

5. In theatre :- Curtains and fly systems in theaters are controlled by a system of multiple pulleys. These pulleys are located high above the stage, out of sight of the audience, and are operated from the side of the stage to raise and lower curtains and scenery during a theatrical performance.

6. Cargo lift system :-A pulley system in a cargo lift system that enables items to be hoisted to higher floors.

7. Blinds on windows :- A pulley system is used to move the blinds up and down on windows. When you pull the blinds cord, the pulley system causes the blinds to open or close.

8. Flagpoles :-Pulleys are used on flagpoles to hoist or lower the flag. When you pull the string on the pulley, the flag moves up and down the pole.

9. Crane, Bulldozer, Escalators : pulley systems are used.

10. Garage doors, Sailboats, Engine, extend ladders, Rock climbers:- Mention system uses pulley for working safer and more effectively.

11. Pulleys are used by rock climbers to aid in their ascent.

12. A perfect example of a pulley is the timing belt in a car.

Types of Pulley

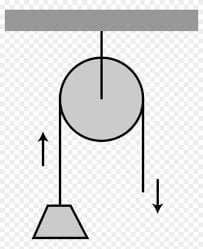

1. Fixed Pulleys

It is defined as ,types of pulley in which pulley is attached to a fixed point and the rope is connected to the object.

The wheel and the axle of fixed pulley are designed in such a way that it lay in only one place. The force on a rope or belt moving around its circumference is changed by a fixed pulley. A flag pole is a good example of a fixed pulley: when you pull down on the rope, the pulley reroutes the force, and the flag is raised.

The pulley is attached to a fixed point and the rope is attached to the object in this type of pulley system. The fixed pulley’s wheel and axle are designed to be stationary. It is made up of a single drum that is attached to a single point.

In these types of pulley, you pull one side of the rope downwards and the other side upwards. You apply the same amount of force to pull it down as you would to lift an object by hand. However, the force’s direction is altered. This is advantageous because when you pull down, you can use your own body weight to push.

The drum of a fixed pulleys are attached to a single spot .While the force required to lift or move an object is the same as lifting it by hand, the fixed pulley allows you to change the direction in which the force is applied.

For example, if you are attached to a bucket that’s pulling water from a well, you can pull sideways with a firm pull for lifting the bucket more comfortably than if you were pulling a bucket of water up hand in the hand vertically. The water bucket feels the same weight, but it’s more easier to lift.

2. Movable Pulleys

It is a types of pulley, in which pulley is attached to the object and one end The rope is attached to the fixed point and the other end of the rope is left free. The pulley is connected to the object that needs to be moved. The rope moves when you pull it, and the pulley lifts the object. This system is ideal for elevating the object beneath you to a higher level.

If both sides of the movable pulley system are fixed and the rope is stretched between fixed points, the system functions similarly to a wheel and axle in that an object can travel along the rope if a force is applied to it.

What is a movable pulley used for ?

A movable pulley is one that can be moved up and down and is connected to a ceiling or another object by two lengths of the same rope. Construction cranes, modern elevators, and some types of weight lifting machines at the gym are all examples of movable pulleys.

The movable pulley did the work of reducing the amount of input force to lift a loads.

The Load is attached directly to the pulley in a moveable pulley, and both can move from one location to another. One end of the rope is attached to a stationary point. It takes less effort or force to move a load with this type of Pulley.

3. Compound Pulleys

The compund pulleys consist of both fixed and movable pulleys which did the work of making load lighter and allow us to change the direction of force.

These are ideal for very heavy loads, but sometimes you need a lot of speed to do the job properly.

It is designed for to putting the the effort you’re loading at less than half the actual load.These systems are typically installed onconstruction sites and on cranes to lift heavy objects such as concrete and steel. It is also known as a combination pulley system.

The advantage of this pulleys :The multiple pulley system is able to multiply the strength and pulling power of the winch, lowering the strain on the winch and the object being pulled.

4. Block and Tackle Pulley

A block and tackle pulley is a system that uses two or more pulleys connected by rope or cable to lift heavy loads. These pulleys are arranged to form a block, and the blocks are then connected so that one is stationary and the other moves with a load.

A block-and-tackle pulley system is made up of several fixed and movable pulses that are arranged parallel to each other; a fixed pulley is aligned with fixed and movable pulleys with movables.

The rope is threaded into the pulley to provide mechanical advantage, which increases the force applied to the rope. These pulleys are typically used for lifting heavy weights or exerting tremendous force in any direction.

Each compound pair of this type is linked to the next pair, and each set reduces the total amount of work needed. Archimedes, a well-known ancient inventor and mathematician, is credited with inventing the pulley system.

5. Speed Cone or Stepped Pulleys

Speed cones are cast iron pulleys having several steps of different diameters on which a belt may run. Speed cones used to wear the velocity ratio between a pair of parallel shaft by simply shifting the belt from one step of the bullet to the other. They work in pairs, one on the counter shaft and the other on the machine spindle. The diameter of the corresponding or steps must be such that same belt can operate no matter how many steps are employed.

In simple language, It is Another specialized pulley system ,which incorporates the basic mechanics of a pulley system while allowing for mechanical adjustments. Cone pulleys are made up of multiple pulleys with decreasing vertical circumference stacked on top of each other to form a cone shape.

This cone shape enables the pulley operator to transfer the speed of the pulleys’ movements, requiring less work with a smaller circumference but producing less work.

Multi-gear bicycles essentially operate on the same system; cyclists can easily shift between smaller gears that propel the bike at a slower speed, and higher gears that require more effort but move the bike farther per revolution.

Uses :- It’s used in places where the driven pulley’s speed needs to be increased or decreased for various jobs, for example :- drill machines and lathe machines.

6. Grooved Pulleys

Grooved pulley for rope, v-belt etc. are the types of pulley generally made entirely of cast iron, but occasionally the arms are made of wrought iron. They are mainly used for the transmission of large power over great distances and the effect of groove is to increase the frictional grip of the rope on the pulley and thus reduce the tendency of to slip.

The grooves on the pulleys are v-shaped, the angle between the two faces bring from 40 degree to 60 degree. The rope rest on the two sides, are not on the bottom of the groove. In guide pulleys, the grooves are semicircular, and the rope rest on the bottom of the groove. The diameter of the rope Pulley is generally not less than 30 times the diameter of the rope.

7. Jockey Pulleys or Rider Pulleys

Jockey pully are used to increase the arc of contact, and also to produce more tension in the belt as shown in the figure. They are mounted near the smaller of the two pulleys in a belt drive and always ride on the slack side of the belt. The pulley presses down the slack side due to having loaded bearing in which it runs

8. Guide Pulleys

Guide Pulleys are used to connect non parallel shafts which intersect and those which do not intersect to guide the belt into the proper plane as shown in the figure. Guide pulleys are also used when the two shafts to be connected are close together. Each portion of the belt, as it passes from one pulley to the other, being taken round part of the periphery of a guide pulley, which is suitable placed.

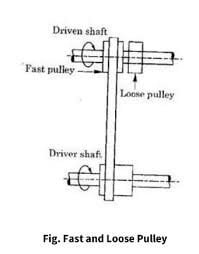

9. Fast and Loose Pulleys

In workshop and factories, power is in certain cases transmitted to the machines from a main line -shift called mainshaft, through an intermediate shaft, called countershaft, and two pulleys known as fast and loose pulley that are mounted on the countershaft. Time useful arrangement enables a machine or stopped at will without stopping the grand loose village to deliver on the shop but the first option family killed on the soft as shown in the figure of the machines of the built-in from the past to the loose Pulley by means of a belt shifter.

The diameter of the loose Pulley is sometimes made slightly smaller than that of fast pulley so that when the belt is on the loose Pulley there is very little tension in the belt.A loose pulley is provided with a brass or gun metal bush and needs efficient lubrication for smooth running.

In simple language, we can say that These pulleys are used for machines that need to be started or stopped quickly. These are two small pulleys that are mounted on a countershaft in pairs. A ‘key’ or some other medium is used to tighten one pulley on the countershaft, and another pulley is fitted through a provision for free rotation.

When the machine is turned on, the belt is attached to the tight pulley. This pulley is referred to as a fast pulley. When it is time to stop the machine, the belt is slipped onto the independent pulley, also known as a loose pulley.

Its main advantage is that we can turn off the machine while the main shaft, which is powered by an electric motor or an oil engine, continues to rotate. For slipping the belt, a lever is provided.

10. Round pulleys

A round belt pulley is a mechanical device that transmits rotational motion around an axle. The round belt pulley accepts a belt, cable, or rope in a groove around the device’s circumference to guide the drive element.

Idlers and drive pulleys for urethane belting on packaging machinery, as well as can cable conveyor systems, are common uses for pulleys.

11. Conveyor Pulleys

These pulleys are used as a driver pulley on the countershaft of machines that have a single electric motor or oil engine and a single countershaft. Their faces are made appropriately broad, and they wear flat belts.

A conveyor pulley is used in the conveyor system to assist in changing the direction of the conveyor belt, operating the belt, and providing tension to the belt.

These are constructed from rolled shells with flexible end discs and locking assemblies. They are mounted on a motor at one end of the conveyor or next to the conveyor.

12. Flat Belt Drive

Flat belt pulleys which are used in transmission systems that are driven by flat belts, typically in high-speed, low-power applications in textiles, paper manufacturing, and office machinery such as computer printers. A flat pulley idler can also be used on the back side of a traditional V-belt.

The flat belt is less expensive than the serpentine belt pulley belt. Flat belts are driven by flat pulleys and idlers and do not require a grooved flat belt pulley. A flat pulley idler can also be used to replace the back end of a traditional V-belt.

One advantage of using this pulley is that in the event of over-torque, the belt may slip, preventing damage to equipment other than the belt.

Types of Flat Belt Pulleys

- Paper pulleys

- Cast iron

- Steel pulleys

- Wooden pulleys

Paper Pulleys

Paper pulleys which are made from the compressed paper fibers and are formed with the metal incenter. These pulleys which e are commonly used for belt transmission from electric motors when distance from center to the center shaft is small.

Cast Iron Pulleys

Pulleys are generally made of cast iron. The rim is attached to the web by the central boss, arms, or spokes. The arms can be straight or curved, and the cross-section is usually elliptical. Cast iron pulleys are typically made with round rims.

When a cast pulley contracts into the mold, the arms become tense and are very prone to breaking. Curved arms bend rather than break. Weapons can be found close to the hub. A crown is a slight convexity. While moving, the crown centers the belt on a pulley rim. The width of the crown can range from 9 mm to 300 mm.

Cast iron pulleys can be solid or split type. Split-pulleys are useful when it is necessary to mount a pulley on a shaft that is already carrying pulleys, etc., or when the ends of the shaft are swollen. There is a gap between the faces, and the two parts are easily tightened on the shaft by a bolt. A sunk key is used for heavy drives.

Steel Pulleys

These pulleys are made of steel sheets, as the name implies. This pulley is composed of two parts that are bonded together. Steel pulleys are outfitted with interchangeable bushings and shafts of varying sizes.

A steel pulley has a coefficient of friction with a leather belt that is at least as good as a cast-iron pulley. They are stronger, more durable, and lighter (up to 40% to 60% lighter) than iron pulleys. These pulleys are typically intended to operate at high speeds.

Wooden Pulleys

Wood pulleys are lighter than cast iron or steel pulleys and have a higher coefficient of friction. These pulleys are two-third the weight of a comparable sized cast iron pulley. They are typically constructed of selected maples that are cut into sections and glued together under high pressure. To prevent war, protective coatings of shells or varnishes keep them from absorbing moisture.

These pulleys are either solid or split with an iron hub secured with screws, or they have adjustable bushes that prevent frictional resistance between them and the shaft from being installed. These pulleys are used for motor drives with a limited contact arc between the pulley face and the belt.

As the coefficient of friction of leather on wood is higher than on the metal, it is claimed that wooden pulley will transmit more power than an iron pulley under the same condition, but they are not so durable as iron.Wooden pulleycan only be used in situation free from excessive dampness or moisture and not subjected to high or varying temperatures.

Materials for Construction of Pulleys

Pulleys can be made of a variety of materials, including cast iron, cast steel or pressed steel, wood, and paper. The cast material should have low friction and wear. Although pressed steel pulleys are lighter than cast steel pulleys, they have less friction and can cause excessive wear in many cases.

Advantages and Disadvantages of Pulleys

Advantages of Pulleys

The main advantage of using pulleys is that the effort required is less than that required for normal weight lifting. In another word, it did the work of reducing the amount of actual force required to lift heavy objects.

It also changes the direction of the applied force. Because of these two advantages, pulleys are an important tool for heavy lifting. It also has a mechanical benefit.

Another advantage of using pulleys is that the distance between the operator and the weight is reduced.

There is a safe distance between them, preventing a disaster.

Pulleys are simple to assemble and inexpensive.

With little effort, a combination of different directional pulleys can change the load’s position.

Even though the pulley system contains moving parts, it requires little or no lubrication after installation.

Disadvantages of Pulleys

The main disadvantage of using the pulley system is that it takes up a lot of space to install and operate.

The mechanical advantage of pulleys can be increased to higher values, but they require more space to be installed.

In some cases, the ropes/belts move over the wheel with no grooves, increasing the likelihood of the ropes/belts slipping from the wheel.

If the system is installed to be used for a long time, it will require maintenance and regular check-ups of the ropes/cables as friction between the wheels and the cables/ropes occurs, causing wear and tear to them.

The continuous use of the system weakens the ropes. While using the system, the rope may break, causing damage to the operator, the surrounding area, and the load being lifted.

Check Out Other Important Topics