In this article we will learn about Thermo electric pyrometer, how it works and what is its working principle.

In all heat-treating practices and in a number of different situations, some equipment are necessary for measuring temperatures.

Mercury boils at 357°C, and thus cannot be used above this the heat-treatments involve temperatures well above temperature. Most of 357°C, so this places a severe limitation on the use of mercury thermometers. They may be suitable for heat-treatments which are carried out below this temperature.

A scientific and reliable method of measuring temperatures is by an instrument called pyrometer. Two types of pyrometers in common use are :

1. Thermo-electric pyrometers

2. Optical pyrometers

These may be employed at any temperature up to about 1,200°C for those made of “base metals” and to 1,500°C for “noble-metals”.

Base metal couples are made from nickel-chromium wire with nickel-aluminium wire for temperatures up to 1200°C ; nickel chromium with constantan wire up to 800°C. Base-metal couples oxidize more readily than noble-metal couples and they have, therefore, a much shorter life than the other. A noble-metal couple consists of one wire of pure platinum and the other of an alloy of platinum and rhodium. This is used for temperatures up to 1500°C. The wires in the noble-metal couple do not oxidize readily.

Working Principle of Thermo Electric Pyrometer

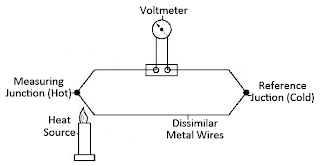

The operation of the thermo-electric pyrometers is based on the principle that when two wires of different metals are joined to form a complete electric circuit, and one junction is at a higher temperature than the other, an electric current flows in the circuit. The magnitude of the current depends upon the metal used, and the temperature difference of the hot junctions.

In the thermo-electric pyrometers the emf set up is either measured by a potentiometer or is allowed to send a current through a galvanometer connected being proportional to the thermo-electric einf. if the resistance of the circuit is constant. Since the thermo-electric emf is really dependent upon the difference of temperature of the two junctions, it is necessary to keep the temperature of the “cold” junction constant if the temperature of the “hot” junction is to be accurately measured.

The complete circuit of the thermo-electric pyrometer. If the high-resistance galvanometer is used, the ballast resistance may be unnecessary. This method is most suitable when the temperature to he measured is very high. The absolute constancy of the temperature of the cold junction is not then of such importance as when the temperature to be measured is low. For measurements of lower temperatures the cold junction maybe contained within a vacuum flask, and maintained at a known low temperature.

It is customary to use copper leads to the indicating instrument, and if neither of the thermocouple wires is copper both of the junction between the thermocouple wires and the copper leads must be in the vacuum flask. Crushed ice may be used in the cold junction flask. Alternatively, the reference junction may be maintained at a steady, through higher, temperature in a small electrically-heated chamber.

Thermo Electric Pyrometer

In the practical application of this principle, an electric meter is connected to two wires which are welded together to form the hot junction.

The two wires forming the junction are known as thermocouple. The three essential parts of a thermo electric pyrometer are the thermo-couple, the galvanometer, and the wires leading from the thermo-couple to the galvanometer, which is so calibrated that instead of indicating electrical units, it reads in degrees of temperature. Fig. 6.10 gives the installation of a thermo electric pyrometer.

Check Out Other Important Topics

Optical Pyrometer Working Principle

Foundry Tools And Equipment – List, Names & Images

Sand Testing Methods – Full Process

Types of Casting Defects – Complete Overview

Moulding Sand – Properties, Types, Process, MCQs

Plant Layout – Types, Objectives, Principles, Advantages

| IC Engine | Important PDFs | Boilers | Synergy Maritime Exam | Naval Arch | MEO Class 4 |

| Interview Questions | Difference Between | Types of Pumps | Auxiliary Machines | Types of Valves | Home |