In this Article ,I have mentioned How to convert purifier into clarifier ?

Beside it,you will also learn listed topic in this Article.

- Difference Between Purifier and clarifier

- Why Clarifier not converted into purifier

- What is Blind Disc

- What is sealing water line

- What is gravity disc ?

Changing purifier into clarifier

- Open the purifier and place the blind disk at the bottom of the disc stack.

- The water outlet is blocked by a seal on the gravity disc.

- Blank off the inlet line of sealing water.

For better understanding watch video:-

https://youtu.be/bdCiOitnjGA

Must read:- Purifier

Can Clarifier change into purifier

Answer is NoIt is because in clarifier there is no water outlet and sealing water line.

Difference between Puri fier and Clarifier

Purifier

- There is holes in the upper disc .

- It Separates water and solid particles.

- It has two Outlet on top, a)Water outlet and b )pure oil outlet.

- There is a Gravity disc on top of disk stack.

- For starting of purifier ,Sealing Water required.

- Top disk with neck

Clarifier

- There is no holes in the lower disc.

- It Separates only solid particles.

- There is No Gravity disc

- Only cleaned Oil Outlet at the top

- Sealing water does not required

- There is Disk without neck

What is blind disc in the purifier ? What is it’s function ?

Blind Disc means the disc is blind.It means there is no holes in the disc.It is used to convert the purifier into clarify. It is inserted at the bottom of the disk stack, because there are no holes.

What is Gravity Disc ?

A ring fitted at the top of disc stack from where water is passing out is called gravity disc.Oil maybe of different densities,so the interface changes.To create the correct line of interface between water and oil it is very important to select correct gravity disc size.

The function of gravity disc are as follows

gravity disc in the purifier is one which controls the output of the quantity of fuel. It is responsible for creating the interface between the oil and water.

Back pressure is maintained by gravity disc.

It is responsible for creating the interface between the oil and water.

Back pressure is maintained by gravity disc.

What is sealing water line?

In a purifier, water sealing is established before introduction of the oil, so that oil filling does not flow through the heavy liquid outlet.

Purpose :-

To seal the water outlet & also to prevent the overflow of oil through the water outlet.

For better understanding ,How purifier change into clarifier and why not clarifier change into purifier, please read full Article .

I am 100 percent sure,After reading this 5 minute article you have no Doubt.

Basic Principle of separation

- Separation as a means of removing impurities from a fuel can be carried out by gravity in a settling tank or by centrifugation of the fuel.

- Both methods work on the same principles that, by subjecting the constant force to fuel, the denser components of the fuel, i.e. water and soil, will be separated from the lighter components , i.e. the fuel itself.

- The gravity acting on the fuel as it passes through the tank slowly separates the denser components from the fuel where they accumulate at the bottom of the tank. The contaminants can then be removed by sludging the tank.

Centrifuging

- Centrifuging is a process by which the gravity effect can be amplified by the use of centrifugal force to the extent that the separation process becomes rapid and continuous. Centrifuges operate, rapidly by spinning a bowl containing the liquid, thus producing the centrifugal force required for separation.

- Its principle of operation of is very simple.

Centrifugal separators used to separate two liquids with different densities (fuel and water) are known as purifiers, and clarifiers are those used to remove solid impurities.

Note:- Purifiers will also remove some solids, and clarifiers will remove small amounts of water as well.

Clarifier

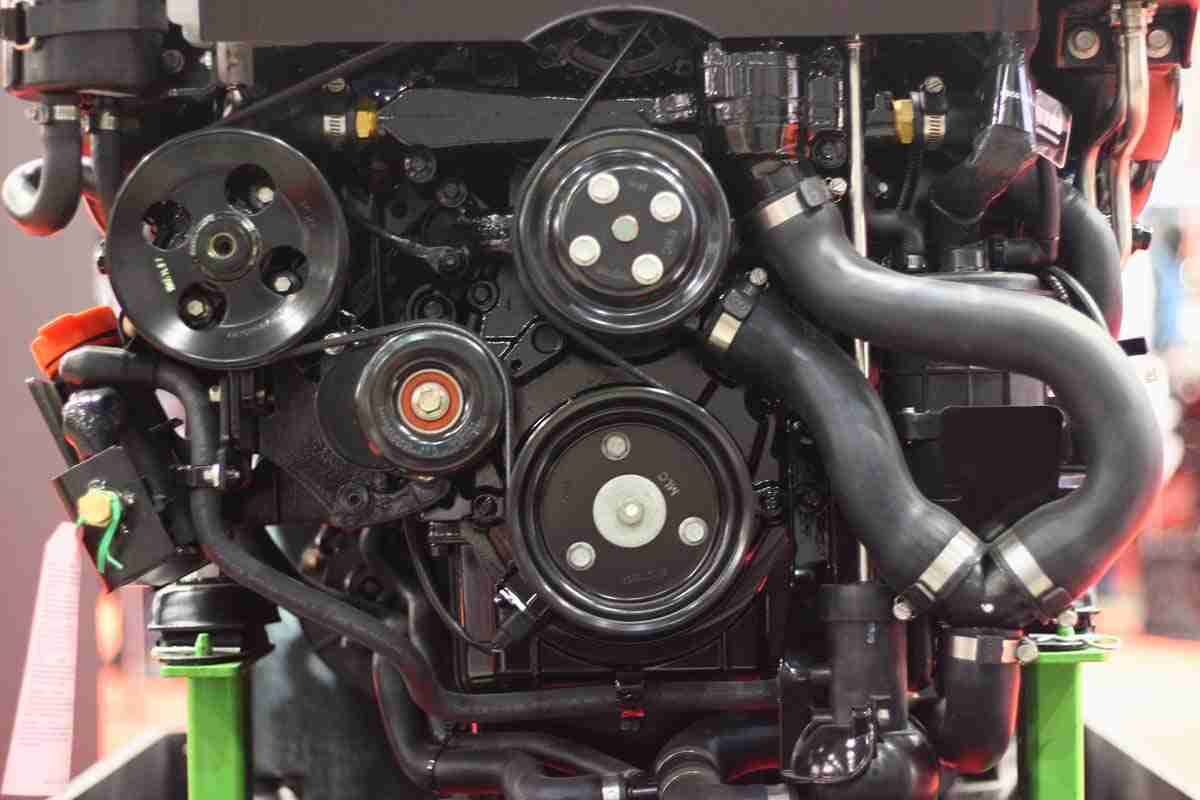

In above figure,the addition of an inlet and an outlet connection forms a simple clarifier.

- Rotational speeds vary by design and range from 7,000 to 9,000 rpm. Efficiency is increased by the inclusion of a number of dicks (up to 150) which increase the surface area and thus help in separation of impurities from fuel. The dicks are placed at a distance of 0.5-0.6 mm.

- After passing through the central passage, the untreated oil is moved by centrifugal forces to the periphery of the bowl and then passes through the disk stack. Here is where the actual separation takes place, in a channel formed between two disks. Two forces are acting on each solid or liquid particle.

The particle is pushed upwards by the oil stream to the centre, while the centrifugal force directs it to the periphery.

The residual force on the denser particles (impurities) will drive them towards the periphery, while the less dense particles (oil) will be directed towards the center of the bowl and will rise to the outlet connection.

Purifier

When a centrifuge is configured as a purifier, the second outlet pipe is used for the discharge of water as shown in figure.

In the fuel oil purifier, the untreated fuel contains a mixture of oil, solids and water, which is separated into three layers by the centrifuge.

Because marine fuel oil usually contains a small amount of water , it is important to prime the bowl each time it runs, or otherwise,all the oil would passes over the side of the water outlet to waste.

The radius of the water outlet is greater than the fuel’s. There is a gravity disc within the water outlet, which did the work of controlling the radial position of the fuel- water interface.

As the fuel centrifuge operates, particulate matter accumulates on the bowl walls.

- If the centrifuge is set as a clarifier, a mixture of water and solid material can form the particulate matter.

- The free water is continually discharged if set as a purifier, thus the particulate matter must consist of solid material.

Notes:- In older machines it is important to stop the centrifuge to manually clean the bowl and the disc stack, but today most devices will discharge the contents of the bowl while the centrifuge operates.