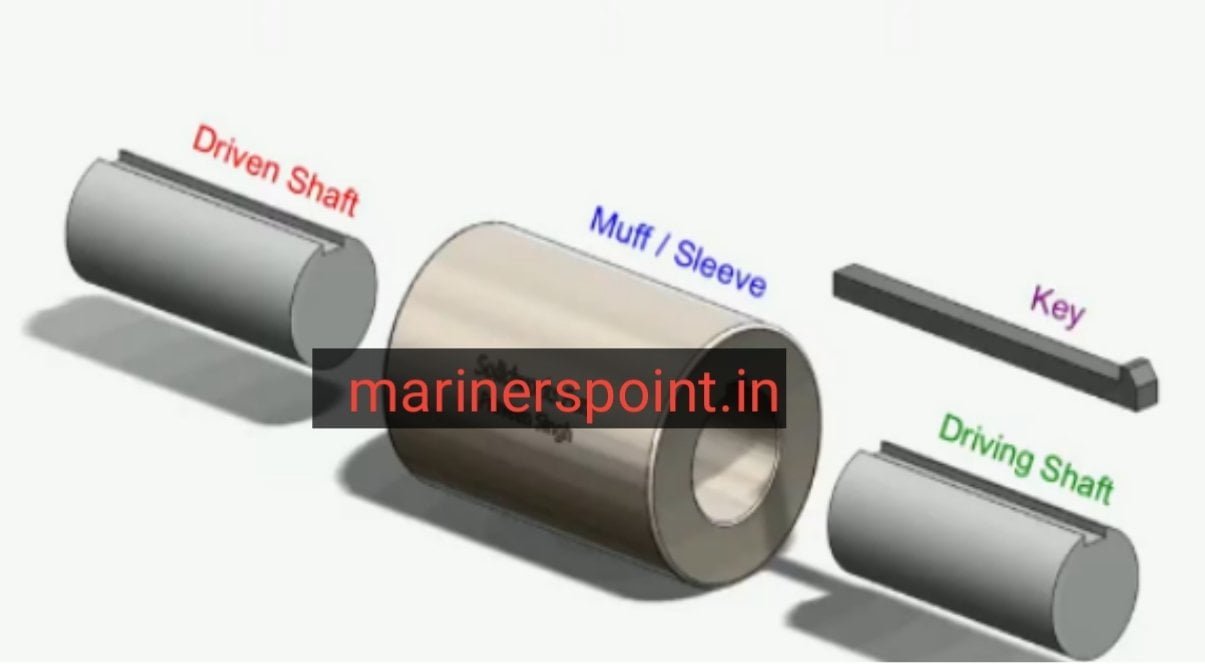

What is Muff Coupling or Sleeve Coupling ?

A Muff coupling / Sleeve Coupling is the simplest type of rigid coupling, consisting of a hollow cylinder with the same inner diameter as the shaft. It is fitted over the ends of the two shafts by the means of a gib head key. Power is transmitted from one shaft to the other shaft by means of a key and a sleeve or muff.

It is type of rigid coupling which consists of cylindrical sleeve or muff keyed to the shafts to be connected for Torque transmission in varied applications.

Note :- A muff coupling is also known as a sleeve or box coupling. It is a type of rigid coupling which consists of a sleeve and a key used to connect the input and output shafts.

The sleeve or muff coupling is designed as a ……….?

Mcqs questions come in the exam with options

A. thick cylinder

B. dun cylinder

C. Hollow shaft

D. Solid shaft

Answer will be C) hollow shaft .

The sleeve or muff coupling is designed as a hollow shaft.

Function of Muff Coupling

It is used to connect two shafts which are perfectly in axial alignment for transmitting power.

Parts of a Muff / Sleeve Coupling

1. Key

2. Shaft ( Driving or Driven Shaft )

3. Muff

Construction of Sleeve Coupling

It is the simple type of rigid coupling ,made up of cast iron. It consists of a hollow cylinder whose inner diameter is the same as that of the shaft. It is fitted over the ends of the two shafts by a sunk key.

The power is transmitted from from one shaft (drive ) to other shaft (Driven ( by means of a key and sleeve.

The muff or sleeve is may be hollow cylinder or made into two halves and bolted together called split muff coupling.

Split Muff Coupling

The half of sleeve made up of cast iron.

The ends of the shaft are made butt to each other’s.

A single key is fitted directly in the keyways of both the shafts

Both the half are held together by means of mild steel studs,bolts or nuts. The number of bolt may be two,three or four.

The advantages of Muff coupling is that the position of the shafts need to be changed for assembling or disassembling of the couplings.

Working

Torque is transmitted from the input shaft ( driving shaft ) to the sleeve through key and from the sleeve to the output shaft (Driven shaft ) through the key again.

Advantages and Disadvantages of Muff Coupling

Advantages

1.It is very simple, becauseit has only two parts; a sleeve and a key.

2.It is safe to use because it has no projecting parts.

3.It has compact constructions.

4.Cpmared to other types of coupling,it is cheaper.

Disadvantages

1.It is difficult to assemble or dismantle.

2.Because it is a rigid coupling, it cannot accommodate any misalignment.

3.It can not absorbs shocks and vibrations due to absence of flexibile elements.

4. It takes up more axial space than other types of couplings.

Lubrication

Muff couplings are rigid and are typically used in systems where no misalignment is expected. These couplings primarily provide an easy and cost-effective method for making proper adaptation between two different shaft sizes. As a result of their sturdy construction, these couplings do not require lubrication.

Read more : Flame Arrester – Introduction, Working Principle

Heat Exchanger – Types | Working | Construction

Diesel Generator Working Principle | Parts And Functions

FAQ ( Frequently Asked Questions )

Where muff coupling is used in ship?

It is used in propeller shafts on ship.

Check Out Other Important Topics

Home IC Engine Electrical Important PDFs Boilers Synergy Maritime Exam Naval Arch Interview Questions Difference Between Types of Pumps Types of Valves MEO Class 4 Auxiliary Machines