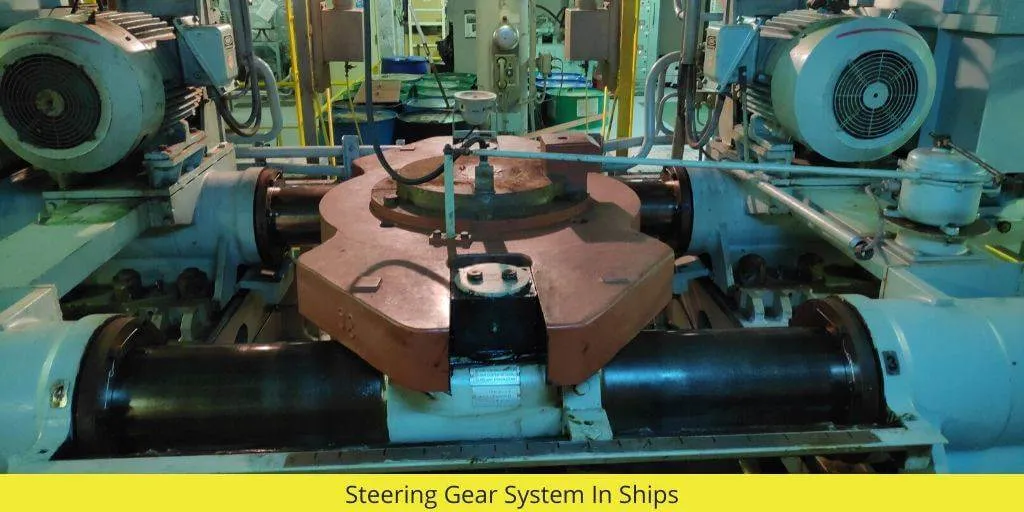

What is Steering Gear ?

Steering gear is the system used on ships to control the direction of the vessel. It allows the ship to turn from port (the left side) to starboard (the right side), or from starboard to port, while it is moving during sailing.

Important Note: The steering gear only works when the ship is in motion. It does not function when the ship is stationary.

Capacity

For optimal performance, a steering gear system must have the capacity to rotate the rudder from 35° port to 35° starboard. Additionally, it should be able to transition the rudder from 30° on one side to 35° on the other side within 28 seconds. This ensures quick and efficient maneuvering of the ship.

Limitations and Efficiency of Steering Gear

One important limitation to note is that the steering gear operates effectively only when the ship is in motion. When stationary, the system will not function properly, making it crucial for navigation during active sailing.

Must Read : Fresh Water Generator

Main Parts of Steering Gear

The main components of a ship’s steering gear system are crucial for controlling the rudder and, by extension, the ship’s direction. Here are the key components:

1. Rudder: The rudder is the primary component responsible for changing the ship’s direction. It is mounted at the stern and moves side-to-side to steer the vessel.

2. Steering Gear Motor : This motor powers the entire steering system, providing the necessary force to move the rudder. It can be hydraulic or electro-hydraulic.

3. Hydraulic Pump: In hydraulic systems, the pump generates pressure to actuate the rudder’s movement. It is essential for providing smooth and controlled rudder operations.

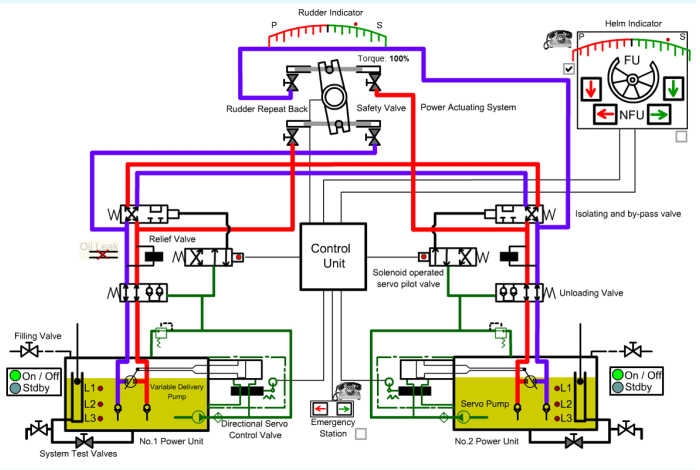

4. Control Unit : The control unit is responsible for receiving signals from the bridge (via the steering wheel or autopilot) and converting them into actions for the steering gear.

5. Ram (Actuator) : The ram or actuator converts the hydraulic or mechanical force from the steering gear motor into movement to turn the rudder.

6. Telemotor : The telemotor transmits steering commands from the ship’s bridge to the steering gear unit, using hydraulic or electrical signals.

7. Steering Gear Transmission Linkages : These mechanical linkages connect the control unit to the rudder stock, ensuring precise movement of the rudder as commanded by the bridge.

8. Rudder Stock : The rudder stock is the shaft that connects the rudder to the steering gear. It transmits the movement from the steering gear to the rudder.

9. Hunting Gear : A feedback device that monitors the position of the rudder and ensures it aligns with the helm’s position, helping to correct any deviations automatically.

10. Relief Valve : A safety component that prevents excessive pressure build-up in the hydraulic system, protecting the system from damage.

These components work together to ensure the ship can steer effectively and safely.

Main Components of Steering Gear System

In the steering system, the steering gear provides a movement of the rudder In response to a signal from the bridge.

3 main parts of steering gear system

a) Control Equipment :- Control equipment convey a signal of desired rudder angle from the steering flat where it is received to activate the power unit and transmission system until the desired angle is reached.

b) Power Unit :- power unit provides the force when required & with immediate effort to move the rudder to the desired angle.

c) Transmission Unit to the Rudder Stock :- Transmission system (steering gear) is the means by which the movement of the rudder is accomplished.

Note :- Control equipment can be hydraulic control equipment ( known as telemotor ) or an electrical electronic control equipment.

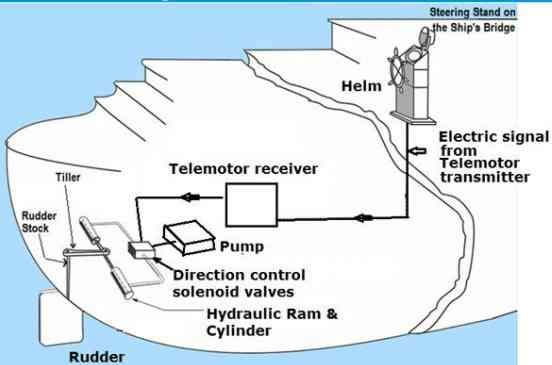

The steering control (Tele-motor transmitter) on the navigation bridge which sends electrical signals to the Tele-motor receiver in the ship’s steering gear room.

This Tele-motor receiver in the steering gear room sends electrical signals to the Direction control solenoid valves.

What are the Types of Steering Gear used on Ship?

1) Electro-hydraulic system

a) Ram type system ( 2 ram or 4 ram)

b) Vane type system

2) All electric system a) Ward Leonard system b) Single motor system

Types of Hydraulic Powered Transmission Unit or Steering Gears

It is of two types :-

a) Ram type ( may be 2 ram or 4 ram )

b) Rotary vane type

Here we will Discuss About Ram Type Steering Gear System

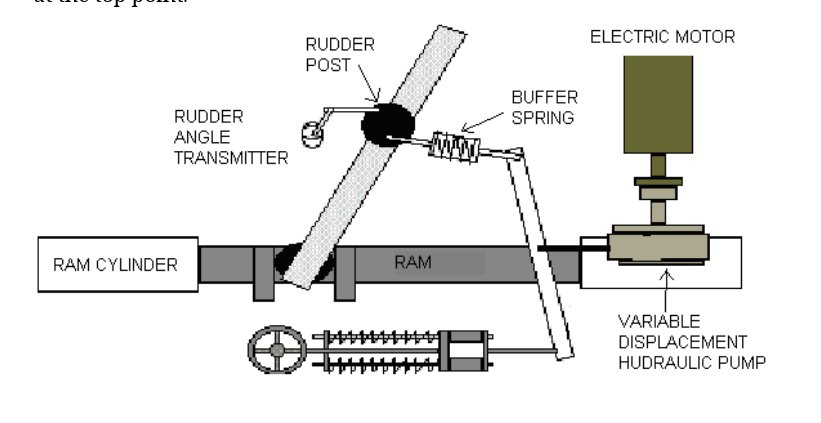

Ram Type Steering Gear System Working

Working

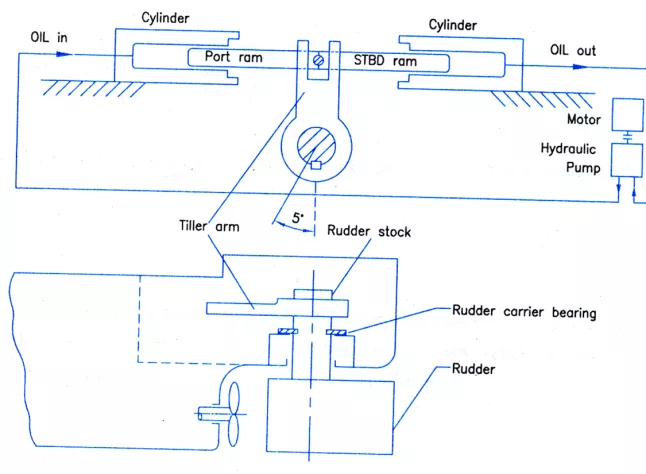

If the oil is pumped into the LHS (port) hydraulic cylinder and drawn from RHS ( starboard) hydraulic cylinder, there will be a left to right sliding movement of the rams. Through the RAM cross head, the tiller arm will move towards starboard and the rudder towards port .

The instant pumping is stooped , movement of tiller arm will stop and rudder will be hydraulically locked in this new position as oil now has no way to leak and is fully blocked within the ram cylinders and vice – versa.

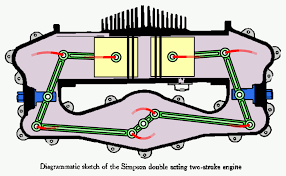

Two Ram Steering Gear Working

Sketch shows the arrangement of a 2 Ram the steering gear.

When the steering wheel is turned signal goes to telemotor receiver through the telemotor transmitter which operates the hunting gear.

Hunting gear int urn Moves the variable delivery pump (hele shaw or swash plate type ) operating spindle from neutral position.

Thus pump start pumping to one hydraulic cylinder and from the other hydraulic cylinder, oil is sucked to pump. And the Ram starts moving and this movement is transmitted through the tiller to the rudder stock and rudder.

The movement of rudder cause the hunting gear to move in such a way that once the desired angle of rudder is reached the pumps operating spindle comes back to neutral positions, and no further pumping & rudder remains in desired angular position.

4 Ram Steering Gear Working

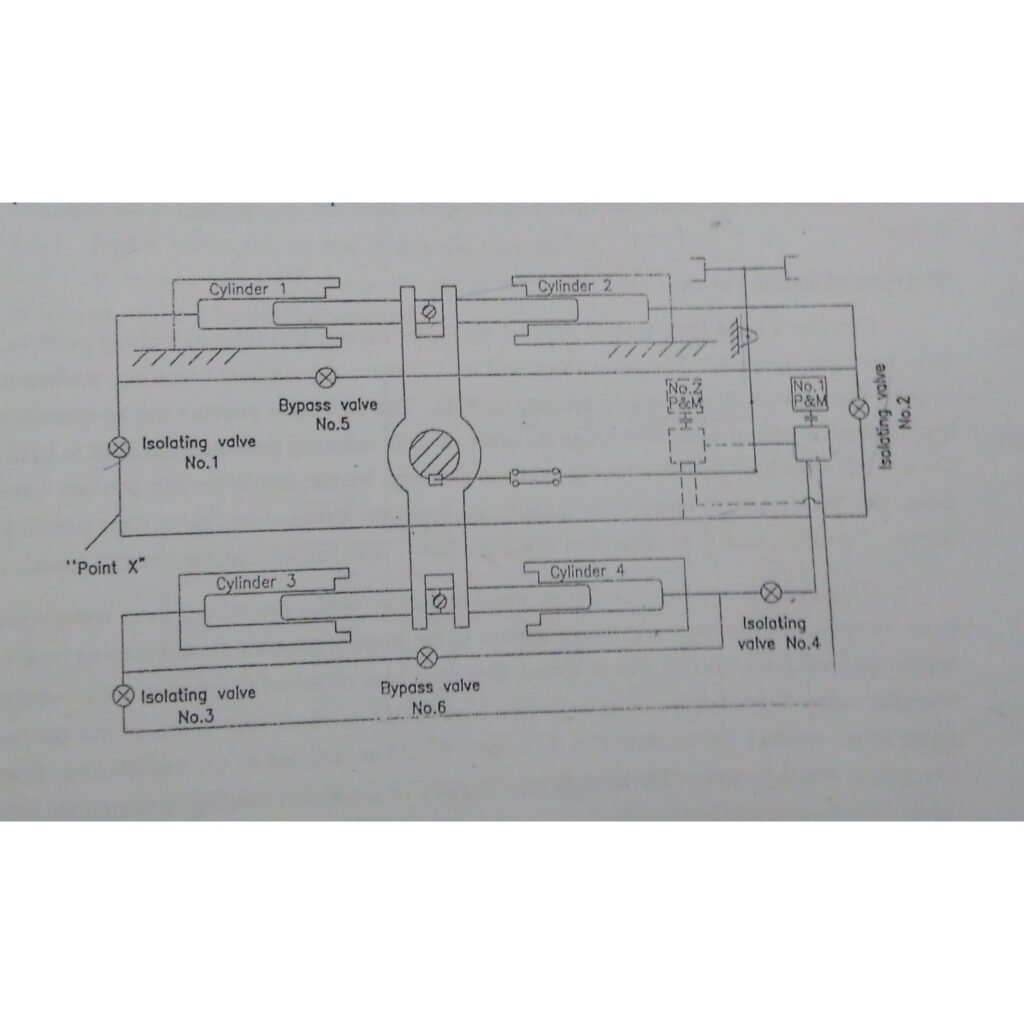

Above Diagram shows the arrangement of a four ram steering gear.

Working

As the signal from the telemotor system operates the hunting gear it actuates the variable delivery pumps to pumping position,thus oil flows to two numbers diagonally opposite cylinder ( say 1 and 4 ) from other two cylinder (two and three ) oil is sucked into the pump.

This causes the rudder to turn in clockwise direction. If due to the action of telemotor system hunting gear is moved to other direction then oil will be supplied to cylinder 2&3 and from 1& 4 oil will flow into the pump and thus the rudder turns in anticlockwise directions.

Turning of the rudder will move the hunting gear in such a way that so that once the desired position is reached , pump operating Lever will bring the pump into neutral position and the desired rudder position will be maintained.

Each cylinder is fitted with cylinder isolating valve. There are two bypass valve and relief valve connecting cylinder 1 and 2 & cylinder 3 and 4.

In case of excessive pressure in the cylinder ( which may occur due to shock on the rudder )

The spring loaded bypass valve will open automatically causes the connected cylinder to bypass.

Replenishing tank is provided into the system to make up any loss of Hydraulic oil .

Safety Arrangements in a Steering Gear System on Ship

A) Isolating valve :- isolating valves are provided at each cylinder & Rotary vane number which when closed it will hold the rudder by trapping the oil in the Chambers.Pumps are also equipped with an isolating valves so that the pump can be totally shut off from the circuit and removed for servicing while the steering is continued with the other pumps.

B) Bypass valve:-. Bypass valves are normally closed but can be opened on two cylinder gear to allow for the use of emergency steering.One pair of cylinder can be bypassed on a four cylinders – gears while the other pair of cylinders provide emergency steering at reduced torque.

C) Relief valves :- relief valves are provided between complementary pair of cylinder or Chambers of vane gears. They are set to lift at pressure above the normal maximum.

D) Shock valves are fitted in pipework of the system between cylinders to prevent excessive shock load from the rudder due to heavy seas being transmitted to the hydraulic system.

What are the Safety Devices for Steering System

Safety Devices are

- Hunting gear

- Buffer spring

- Angle adjusting stop (Hand over position limit switch)

- Double shock valve

- Relief valve

- Tank level alarm (oil)

- Over load alarm

How does a ship steering gear work ?

The ‘control force’ for turning is triggered off the wheel at the helm, which reaches the steering system. The steering system generates a torsional force at a certain scale, which is then, in turn, transmitted to the steering gear that rotates the steering wheel.

What is Emergency Steering ?

The emergency steering system, as the name suggests, is a system that is used during the failure of the ship’s main steering system.

A situation can occur in which the remote control operation may fail to work and their can be a sudden loss of steering control from the bridge. This can be due to sudden power failure, any electrical fault in the system or the control system which includes faulty tele-motor or servo motor which is used for transferring the signal from bridge to the steering unit.

An emergency steering system is used to control the steering of the ship in such an emergency situation by manually measuring it from inside the steering gear room.

Frequently Asked Questions ( FAQ )

What is the purpose of steering gear?

Its purpose to turn the ship from port to starboard and Vice-versa. Its purpose in car to turn the wheel.

What are the 3 main parts of steering gear system?

The main parts are Transmission , power unit and Control Unit.

What are the 2 types of steering systems?

1.Hydraulic and 2. Electrohydraulic

What is Steering Ram ?

The steering ram, also known as the steering cylinder, is the most important part of a hydraulic steering system. To ensure proper and precise operation, choose an appropriate steering ram for your application.

What is Follow up and Non follow up Steering system ?

Follow up : – This is the standard steering method, which includes steering angle feedback to the helm. This can be operated manually or automatically.

The ship’s heading can be programmed into the autopilot, which can then compare it to the desired heading and adjust the rudder angle accordingly.

Non Follow Up– Normally used only for backup purposes. Each steering gear unit has a single lever; by moving the lever in one direction, the rudder begins to turn; the rudder continues to turn until the lever is released or it reaches the limit of its operation.

What Do You Call Someone who Steers a Ship ?

A helmsman or helm is a person who steers a ship, sailboat, submarine, other type of maritime vessel, or spacecraft.

Why is Steering Test rudder angle 35 Degree to 30 degree ?

It is because the point at which it is reached can be exactly judged as it crosses 30 degree. And As hunting gear puts pump stroke to zero, the rudder movement slows down progressively as it approaches 35 degree.